Airports

Fulfilling the rigorous requirements of the airport industry

With years of hands-on experience in airports, we provide tailored solutions to meet the unique demands and expectations of the industry, ensuring exceptional reliability, performance, safety, quick delivery times, and support through a global network.

In addition to our premium belting products, you consistently benefit from our expert, solution-focused consulting and services. Whether it’s for baggage handling, screening and detection systems, or aircraft loading and unloading, we offer the ideal solution for every application and process step.

We offer the perfect solution for your challenges.

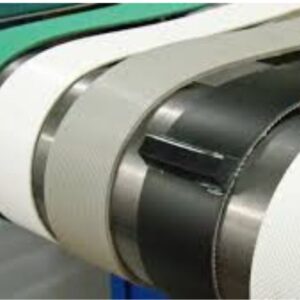

Directional stability

Anti-static properties

Friction on belts used in airport applications can lead to electrostatic charge build-up, which may interfere with electronic equipment, attract dust, and create issues for staff and passengers. Newtop Engineering’s belts are equipped with antistatic yarns to minimize the build-up of static electricity.

Operational in high/low temperatures

Although many airport operating environments maintain normal ambient temperatures, factors such as location and season can result in higher or lower temperatures and humidity levels. Newtop Engineering’s belts are designed to perform efficiently in conditions ranging from -30°C to +70°C, and can withstand humidity levels up to 100%.

Flame-retardance

Ensuring the protection of people, machinery, and buildings from fire is a top priority. Newtop Engineering’s belting solutions support fire safety at your airport by fully complying with international flame retardance standards such as ISO-340, ASTM D-278, or UL94, depending on your region.

Energy-efficient features

With a growing emphasis on environmental performance, airports are increasingly focused on saving energy and reducing carbon emissions. Newtop Engineering’s durable Eff-line energy-saving airport belts offer lower energy consumption and help reduce carbon emissions.

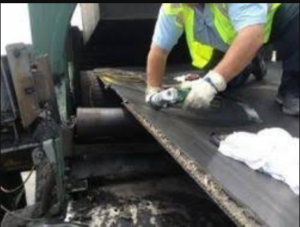

Impact resistance

As baggage is placed on the belts, often with sharp edges that can cause impact, the belts need to be exceptionally sturdy and resistant to cutting. Wear- and impact-resistant materials ensure a long lifespan in all airport applications. Newtop Engineering offers the ideal materials and designs to meet your most demanding application requirements.

Low noise operation

Low-noise operation is especially important at airports, where staff and passengers are frequently exposed to the belts. Newtop Engineering’s belt designs, featuring a low-noise fabric construction, help reduce noise on slider beds, creating a better working and traveling environment.