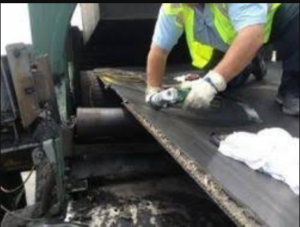

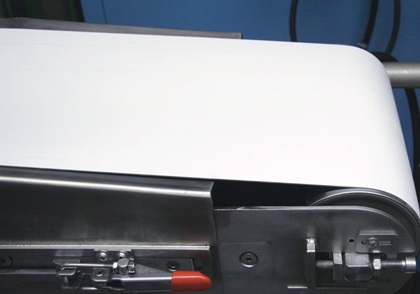

Light Conveyor Belts

The versatile solutions for lightweight conveying

Light conveyor belts are utilized across a wide range of industries, including airports, distribution centers, electronics, agriculture, gypsum board production, and wood panel manufacturing. These belts are designed to handle various general conveying tasks such as induction, transfer, and checkout, in addition to functions like sorting, metering, inspection, packaging, and more. Newtop Engineerings offers effective solutions for all these applications.

Newtop Engineerings offers a variety of light conveyor belts made from chemical and abrasion-resistant materials. These belts feature antistatic and low-noise characteristics, along with energy-saving and flame-resistant treatments, to meet your most challenging application needs.

PVC belts

PVC belts encompass a diverse range of products created using various technologies and raw materials. This versatility enables Newtop Engineerings to offer optimal solutions tailored to meet specific application requirements.

Energy-saving belts

Newtop Engineering’s energy-saving belts are specifically engineered to reduce operating costs. A special lubricant is applied to the running side, providing a very low coefficient of friction between the belt and the slider bed. This low friction reduces the energy required to move the belt, resulting in a significant reduction in energy consumption—potential savings of up to 45%.

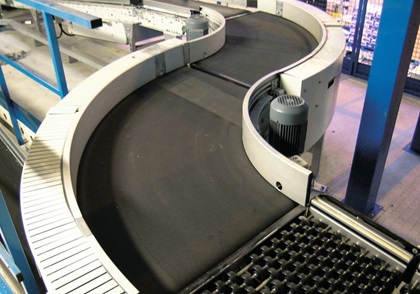

Flame-retardant belts

Newtop Engineering’s flame-retardant belts provide enhanced safety in the event of a fire. These belts are equipped with a self-extinguishing additive that extinguishes flames within seconds, preventing the spread of fire. Compliant with ISO-340 standards, they are widely used in airports and distribution centers.

General purpose belts

Newtop Engineering’s flame-retardant belts provide enhanced safety in the event of a fire. These belts are equipped with a self-extinguishing additive that extinguishes flames within seconds, preventing the spread of fire. Compliant with ISO-340 standards, they are widely used in airports and distribution centers.

Premium line belts

Newtop Engineering’s Premium Line belts provide cutting-edge PVC belting solutions. These belts are produced using a hot-melt coating process with top-grade PVC granules. The combination of high-quality PVC and advanced fabric belt carcasses ensures outstanding performance and a long service life.

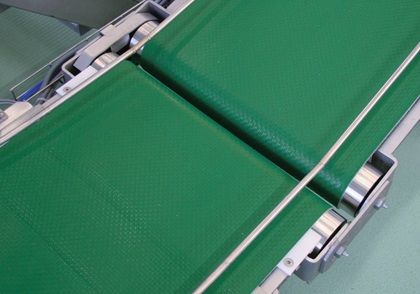

Self-tracking elastic belts

Newtop Engineering’s self-tracking elastic belts require no additional tracking or tensioning devices, eliminating the extra costs associated with belt guide profiles, pulley grooves, and slider beds. This range is antistatic and flame-retardant, and its simplified tensioning system makes maintenance and replacement much easier compared to conventional fabric belts.

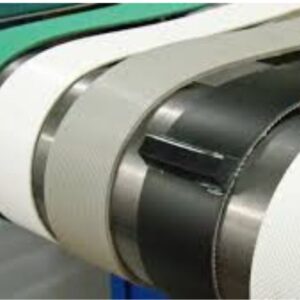

TPU belts

TPU belts deliver exceptional performance, especially when small diameters and high abrasion resistance are essential. They represent the premium segment of the light conveyor belt range, designed for the most challenging applications by Newtop Engineerings.

Crosslinked PUR belts

Crosslinked PUR belts are highly conductive and are recognized as cutting-edge solutions for the electronics sector. These belts are made with polyester or polyamide fabrics coated with cross-linked polyurethane, providing exceptional abrasion resistance during the goods accumulation process. Newtop Engineerings specializes in producing these advanced belts to meet industry demands.