Eff-Line

Lower your operating costs while reducing your carbon footprint.

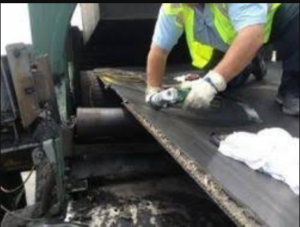

Newtop Engineerings fabric conveyor belts significantly decrease application running costs by reducing energy consumption by as much as 45%. Their unique impregnation process minimizes sliding friction, enhancing durability and extending the lifespan of the belts. This results in fewer belt replacements, leading to even greater savings.

Using Newtop Engineerings belts also has environmental benefits, as their lower energy consumption leads to reduced CO2 emissions. This translates into lower life-cycle operating and maintenance costs, along with a smaller carbon footprint.

Newtop Engineering Eff-Line

Belting benefits

- Reduced running costs

- Energy savings of up to 45%

- Longer belt lifetime

- Fewer belt replacements

- More environmentally friendly solution

Energy efficiency with the Newtop Engineering Eff-Line

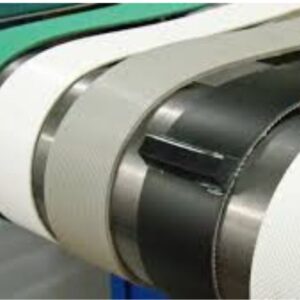

Newtop Engineering Eff-Line belts are engineered to minimize sliding friction between the belt and the conveyor, as higher sliding friction leads to greater energy loss. Sliding friction accounts for up to 60% of energy loss in a belt. With water-based impregnation on the running side, these belts significantly reduce the dynamic coefficient of friction, resulting in longer belt lifespans and fewer replacements.

See how Newtop Engineering Eff-Line belts help you save energy and lower operating costs.