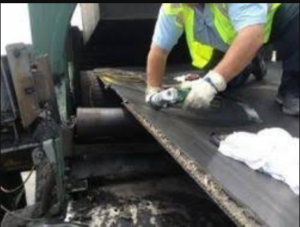

Heavy Conveyor Belts

Reliable powerhouses for demanding processing tasks.

Industries worldwide, including airports, distribution centers, and manufacturers of marble, stone, metal, glass, tires, and plastics, rely on heavy conveyor belts for a wide range of applications such as cutting, punching, stamping, check-in, acceleration, accumulation, and incline loading and unloading.

Newtop Engineering offers an extensive selection of belts tailored to meet diverse needs, including resistance to cuts, wear, oil, and impact, as well as high rigidity, permeability, flame retardance, adhesive or non-adhesive surfaces, temperature resistance, and other specialized properties to suit specific application requirements.

Heavy Conveyor Belts

Nonwoven belts

Newtop Engineering’s nonwoven belts are designed with a unique construction, featuring a central strength member protected by needled, felt-like covers on both the top and bottom. The carcass is often saturated with various PVC or rubber blends to deliver essential properties such as optimal coefficient of friction, flexibility, and resistance to chemicals and abrasion, depending on the application. This design ensures quieter operation compared to traditional interwoven belts, along with additional advantages like a fray-resistant structure.

Flame-Retardant Belts

Newtop Engineering’s flame-retardant belts feature a carcass saturated with a special flame-retardant PVC compound, ideal for use in airport baggage or parcel handling applications. These are known as Trackmate Package Handling belts.

Ulti-Mate Belts

The Ulti-Mate belt carcass is typically saturated with various rubber compounds, providing excellent abrasion and chemical resistance, making them suitable for digital cutting tables, package handling, and more demanding processing applications.

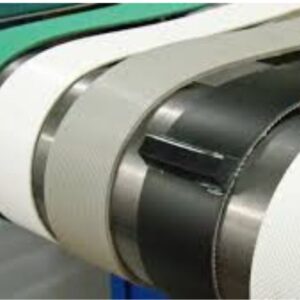

Woven belts

Newtop Engineering’s woven belts include both interwoven and solid woven polyester belts designed for specialized applications. The interwoven belts offer a great balance of durability and cost-effectiveness, providing excellent value for general conveying needs. The solid woven construction makes these belts perfect for use in RF ovens and air gravity conveying.

Allveyor General Purpose Belts

Newtop Engineering’s Allveyor general purpose belts are interwoven and coated with various PVC compounds and top cover profiles, making them suitable for a wide range of general applications across multiple industries.

Flame-Retardant Belts

The flame-retardant belts from Newtop Engineering feature a strong interwoven carcass that is highly resistant to punctures and tears. These belts are coated with a special flame-retardant PVC compound, ideal for airport baggage or parcel handling applications, and are referred to as Allveyor Package Handling belts.

Woven rubber belts

Newtop Engineering’s woven rubber belts, also known as plied rubber belts, are constructed with two or three layers of fabric that are bonded with rubber. These belts are specifically designed to meet the stringent requirements for flame retardance, strength, and abrasion resistance, making them ideal for airport baggage handling and parcel handling applications.