Machine Tapes

Versatile solutions for printing and paper applications.

When you need high-quality machine tapes for conveying, accelerating, decelerating, positioning, or folding paper materials in your operations, you can rely on Newtop Engineering. Our machine tapes are backed by years of expertise, ongoing research, and strong relationships with the printing and paper industry.

Newtop Engineering’s Hamid, polyamide, and polyurethane machine tapes are crafted with abrasion-resistant NBR covers or other surface materials tailored to specific applications. These highly efficient belting solutions provide consistent grip, exceptional reliability, and a long service life.

Machine Tapes

Ntmid machine tapes

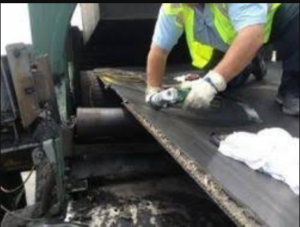

Newtop Engineering’s Hamid machine tapes can be easily joined by fusing the ends together without the need for adhesives, using the Flexproof or Quickmelt methods. This process ensures uniform flexibility across the entire length of the tape, resulting in a superior product. Additionally, it offers significant cost savings by reducing maintenance needs and minimizing machine downtime.

- Simple and fast adhesive-free joining methods

- Uniform longitudinal flexibility (thanks to the adhesive-free joint)

- Low energy consumption, due to high longitudinal flexibility

- Excellent reversed bending and flex fatigue properties

- Copes with small pulley diameters

- Good dimensional stability, low sensitivity to humidity

- High abrasion resistance

- Application-oriented surface properties, gentle treatment of transported goods

- Elastic types available. They are suitable for short center distances and transport of low weights. Despite their elasticity the belts remain dimensionally stable after running-in. They do not require tensioning devices. This allows a simpler machine design and saves costs.

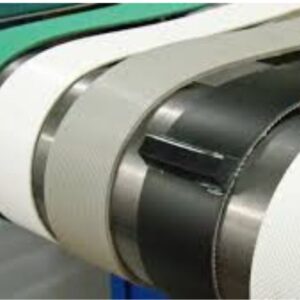

Polyamide Machine Tapes

The traction layer of Newtop Engineering’s machine tapes is highly resilient, capable of handling intermittent overloads without causing residual elongation. This eliminates the need for retensioning and helps avoid costly and time-consuming machine downtimes.

- Good dimensional stability

- Can cope with intermittent overloads, very robust and forgiving

- Very good reverse bending and flex-fatigue properties

- High abrasion resistance

- Application-oriented surface properties, gentle treatment of transported goods

Polyurethane machine tapes

Newtop Engineering’s fine textile-structure friction covers, crafted from TPU, are specifically designed for belt surfaces experiencing high stress, offering best-in-class abrasion resistance. The tape can be easily joined by fusing the ends together without adhesives, using the Flexproof or Quickmelt methods. The elastic TPU foil traction layer allows for fast installation, minimizing machine downtimes.

- Simple and fast adhesive-free joining method

- Uniform longitudinal flexibility thanks to the knock-free joint

- Best in class abrasion resistance

- Constant and gentle grip structure

- Gentle treatment of transported goods

- Elastic types are available They are suitable for short center distances and transport of low weights. Despite their elasticity the belts remain dimensionally stable after running-in. They do not require tensioning devices. This allows a simpler machine design and saves costs.