Elastomer Covered

Conveyor Belts

Strong belts for demanding applications.

Newtop Engineering’s elastomer-covered conveying and processing belts, made with NBR or EPDM rubber, provide reliable and durable solutions for applications in challenging production processes and harsh environmental conditions.

The belts are designed with high abrasion and temperature resistance, a consistent coefficient of friction, and an extended service life. Newtop Engineering’s elastomer-covered belts are ideal for a diverse array of applications across various industries, including materials handling, paper manufacturing, paper and board converting, and packaging.

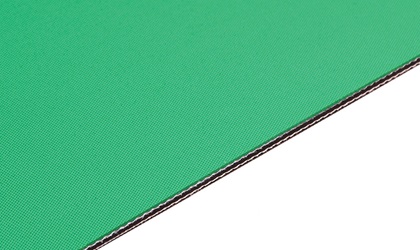

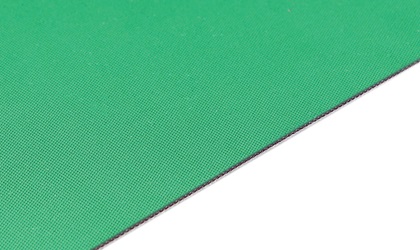

EPDM Cover and PET Traction Layer

Key Features:

- High and consistent coefficient of friction

- Robust

- Resistant to variations in humidity and dimensionally stable

- Antistatic

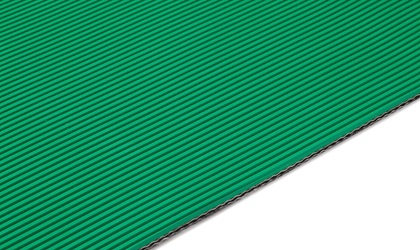

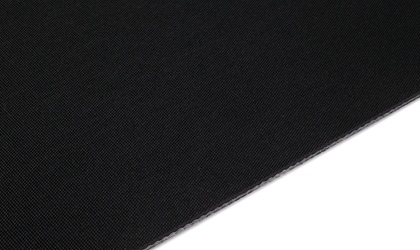

NBR Cover and PA Traction Layer

Key Features:

- Abrasion resistant

- High and consistent coefficient of friction

- Robust forgiving in case of short-term shocks

- Antistatic

NBR Cover and PET Traction Layer

Key Features:

- Abrasion resistant

- High and consistent coefficient of friction

- Robust forgiving in case of short-term shocks

- Antistatic

- Oil resistant

Browse the extensive range of

Newtop Engineering belts, accessories,

and conveyor components.

Industry solutions

Materials handling and distribution centers

Newtop Engineering’s Hamid machine tapes can be easily joined by fusing the ends together without the need for adhesives, using the Flexproof or Quickmelt methods. This process ensures uniform flexibility across the entire length of the tape, resulting in a superior product. Additionally, it offers significant cost savings by reducing maintenance needs and minimizing machine downtime.

High abrasion resistance

- Reliable conveying properties

- Long belt life

Firm grip during processing

Copes with rough working conditions

Abrasion and wear resistance

- Supports steep inclines with angles from 30° to 45°

- Belt does not need cleats – easier to clean

- Less space needed since steep inclines have a smaller footprint

- Reliable conveying properties over time

- Precise processing

- High and consistent machine throughput and sorting performance

- Long belt life – low lifecycle costs

Paper, printing and cardboard

High-speed processes and sensitive, often heavy products require the right combination of belt features to achieve high-quality results. Debris from a processing belt, as well as marking and scratching, can easily compromise product quality. Newtop Engineering’s high abrasion resistance helps extend belt life, ensuring consistent performance.

High abrasion and wear resistance

- Reliable conveying properties

- No wear debris on your products

- Long belt life

Good dimensional stability

- No retensioning required

- Reduced machine downtimes

Resilience

- Forgiving in cases of short-term overload

- Copes with demanding application conditions, e.g. acceleration forces, ‘stop and go’ operations

- No retensioning when installed with adequate tension – reduced machine downtimes

Consistent coefficient of friction Your benefits:

- Reliable conveying properties over time

- Precise processing

- No marking of printed products

- High and consistent machine throughput

- Long belt life – low lifecycle costs

Recycling of aluminum cans, glass, and plastic bottles

Belts used in reverse vending machines and other recycling processes must frequently resist liquids and oil residues. The need to transport various types of goods, including glass and plastic bottles, as well as cans, requires strong and durable belts to ensure smooth and reliable operation. Newtop Engineering provides belts specifically designed to meet these rigorous demands.

Dimensional stability

- No retensioning

- Reduced machine downtimes

High abrasion resistance

- Reliable conveying properties

- Long belt life

Consistent coefficient of friction

- Reliable conveying properties over time

- Precise processing of transported goods

- High throughput and sorting performance

- Long belt life – low lifecycle costs