Monolithic Belts

The hygienic solution for wet food applications

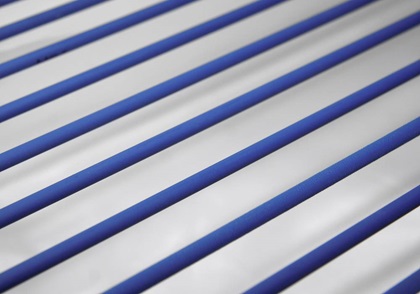

Monolithic belts from Newtop Engineering are designed for wet applications, primarily in the food industry, as well as in materials handling and other sectors. Our fully extruded monolithic belt design, produced with advanced manufacturing technology, meets the highest hygiene standards while ensuring exceptional performance, reliability, and cost-effectiveness.

Newtop’s food-grade monolithic belts are FDA/USDA/USDA Dairy approved and comply with EC regulations. Made from materials that resist water, oil, grease, and other fluids, these belts are also chemical- and abrasion-resistant, with various surface textures available to meet specific application needs.

Monolithic Belts

Newtop Cleandrive

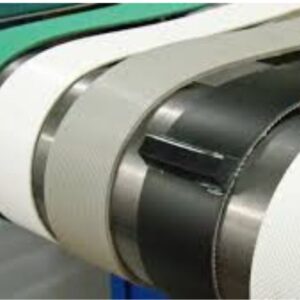

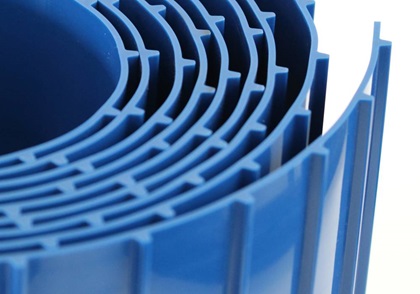

Newtop Cleandrive aramid-reinforced monolithic TPU conveyor belts are globally recognized for their safe and hygienic performance in food processing. Proven across diverse applications, Newtop Cleandrive belts come in two types: sprocket-driven positive drive and pulley-driven friction drive.

The fully extruded monolithic design meets the strictest hygiene requirements of the food industry, delivering exceptional performance, reliability, and cost-efficiency.

Extruded belts

Newtop’s extruded belts are available in various materials, thicknesses, and shapes (including round belts, V-belts, and T-shaped belts) and feature a range of surface properties and structures. Designed for high flexibility and directional adaptability, they are crafted to meet specific application requirements.

Newtop’s extruded belts are widely used in conveying and driving applications and are installed globally on linear conveyors and diverters. Each belt type is selected based on the unique demands of the application.

Monolithic flat belts

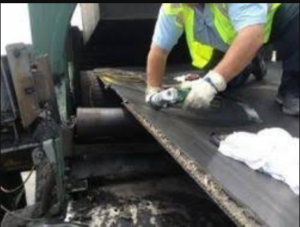

Newtop’s extruded monolithic flat belts are ideal for short in-feed and out-feed applications, where their flexibility allows smooth handling of various product sizes. The belts’ monolithic, no-fray design ensures they are safe for processing unwrapped food items. Thanks to the material’s elasticity, no take-up is required, and in emergencies, the belts can be quickly replaced, reducing machine downtime significantly.