Seamless and Grabber

Belts

Tailored solutions for optimal performance

Newtop Engineering’s seamless belt portfolio includes woven endless and knitted endless belts, along with both synchronous and non-synchronous endless substrates. These belts are coated without splices or seams, ensuring consistent physical properties throughout their entire service life.

Our advanced manufacturing techniques and precise material selection enable tailored designs that meet your specific application needs. Newtop’s seamless belts offer lower lifecycle costs and deliver smooth, vibration-free performance, even at high speeds.

Belt Design

Newtop Engineering manufactures seamless belt substrates (fabric) as endless on looms or knitted in a tubular form. Threads are wound in a spiral along the belt’s running direction, with the belt’s circumference defined by the spiral diameter, and the desired width achieved by slitting the tube. For optimal properties and dimensional stability, the belt substrate is coated with a specialized elastomer and treated through a unique thermal process. Newtop seamless belts are available in stable, semi-stable, semi-elastic, and elastic variations.

Seamless Belts

Newtop GRABBER seamless belts

Newtop Engineering’s GRABBER belts are tailored for applications that require product feeding or pulling, supporting both synchronous and non-synchronous motions. The cover compound is selected to achieve the desired levels of friction and abrasion resistance. Newtop GRABBER belts are further segmented by application type. GRABBER seamless belts are primarily used in folder gluer (FG) or feeding applications where non-synchronous motion is needed. GRABBER timing belts, on the other hand, are ideal for Vertical Form Fill Seal (VFFS) and other pulling applications that require synchronous motion.

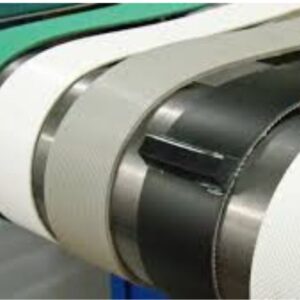

Traditional seamless belts

Newtop Engineering’s seamless belts are crafted by weaving or knitting a circular “tube” of fabric material. These belts are then coated with various rubber or plastic materials, depending on application requirements. Due to their seamless design, they offer exceptional strength for their thickness and can be produced with tight length tolerances.

Power Transmission Belts

Newtop’s seamless power transmission belts are ideal for light-duty applications such as lathes, grinders, vacuum cleaners, and spindle drives. They are available in various strengths, tailored to different fabric designs.

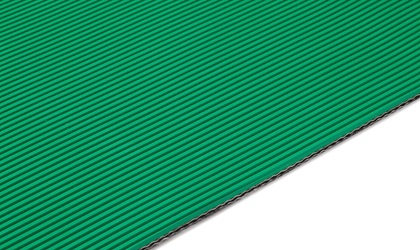

Conveying Belts

Newtop’s seamless conveying belts are used for transporting lightweight items, typically at higher speeds, including paper, currency, tickets, and envelopes. Available in multiple strengths, these belts offer different friction levels, achieved by selecting specific top cover compounds.

Endless woven belts

Newtop Engineering’s endless woven processing belts are tailored to meet specific application needs and are available in either seamless or woven endless designs. The fabric is coated with TPU, DPU, PVC, or silicone based on application requirements. Various belt strengths are achieved by adjusting the weave design, and the belts are further categorized by industry.

EPDM Cover and PET Traction Layer

Key Features:

- High and consistent coefficient of friction

- Robust

- Resistant to variations in humidity and dimensionally stable

- Antistatic

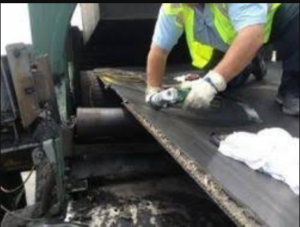

Coil Wrapper, Steel Wrapper or Coil Winder Belts

These belts are utilized in metal production processes, including steel, aluminum, and copper, where they coil the material after production and prior to cutting into sheets. Designed with heavy-duty construction, they withstand the abrasion, cutting, and emulsions involved in the process. The covers are typically made with a thick, durable duroplastic compound. Newtop ensures these belts meet the high demands of metal production.

Silicone processing belts

Silicone Processing Belts are used in various high-temperature applications, including the production of balloons, trash bags, and surgical gloves. These belts feature a silicone cover compound and an endless woven polyester carcass. For applications requiring extreme temperature resistance, aramid is used instead of polyester. Newtop provides these belts to meet the specific demands of high-temperature processes.

Rotary molder belts

Rotary molder belts are used by many different biscuit manufacturers, featuring every kind of dough. The belt fabric is woven endless with real selvage belt edges. Natural fibers such as cotton are standard materials due to their excellent extraction behavior that absorbs fat and moisture from the biscuit dough.