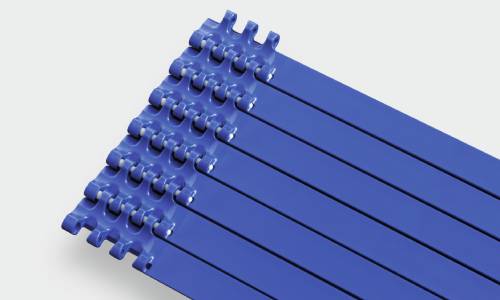

NewtopLINK Plastic Modular

Belts

The many advantages of plastic modular belts

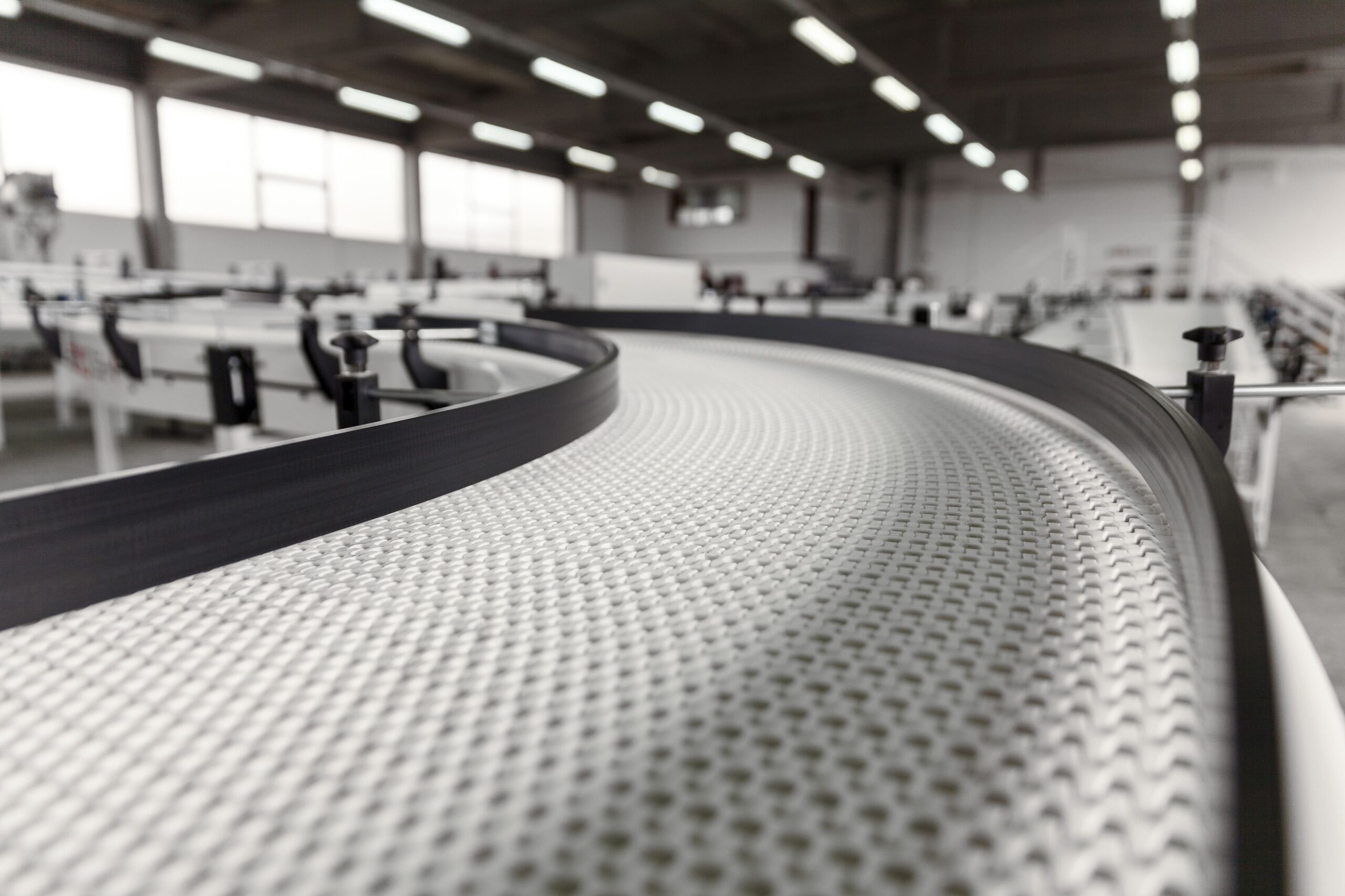

Newtop Engineering’s LINK range of plastic modular belts boasts over 20 years of proven performance in the industry. Our portfolio includes more than 150 different belt styles in a variety of material and color combinations.

Newtop LINK plastic modular belts offer numerous benefits, including long lifespan, high strength, and ease of repair and maintenance.

Why NewtopLINK?

Positive Drive and Tracking

Plastic modular belts from Newtop Engineering do not require pre-tensioning and are unaffected by mistracking issues often caused by inadequate conveyor design or heavy contamination. The positive drive provided by sprockets prevents belt slippage and ensures smooth operation, resulting in significantly reduced maintenance and downtime.

Resistance to Extreme Conditions

Newtop plastic modular belts operate safely and reliably across a wide range of conditions and temperatures, from -70°C to +240°C. The Newtop LINK product range offers solutions for extreme temperature variations, high humidity, aggressive chemicals, cutting operations, product impact, high speeds, and abrasive environments.

Quick Repair and Maintenance

While it is uncommon for plastic modular belts to require maintenance or repair, if necessary, they can be easily opened using simple tools like a screwdriver. Repairs can be completed quickly without the need to replace the entire belt, minimizing downtime. Additionally, since plastic modular belts do not require lubrication, no extra maintenance is needed.

Suitable for Aggressive Chemical Agents

In food applications, belt sanitation is crucial for meeting customer safety requirements. To maintain high safety standards, all equipment and belts must be thoroughly cleaned with aggressive detergents before being rinsed.

Newtop LINK engineered plastic materials provide exceptional resistance to the cleaning agents commonly used in the food industry.

Longer Lifetime

Under standard conditions, plastic modular belts typically have an extended lifespan, lasting for years with minimal maintenance and no decline in performance.

High Strength

Compared to other belting solutions, plastic modular belts offer superior strength, making them capable of handling the most demanding industrial applications. They are also suitable for accumulation and diverting tasks, which can impact the performance and longevity of other belting options.

Wide Range of Surfaces

Newtop LINK plastic modular belts come in a diverse array of surfaces to deliver the specific properties needed for various applications. From flush grid to roller top, there is a surface option that will meet the requirements of your belting application.

Industry solutions

Meat, Poultry and Seafood

NewtopLINK for

protein processing

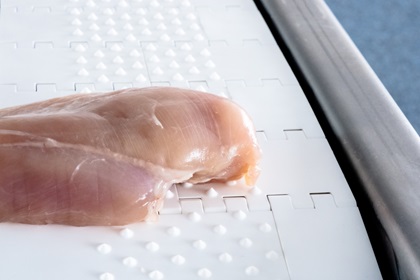

Newtop’s plastic modular belts are specifically engineered to meet the demanding standards of the protein processing industry, including applications involving fresh or frozen meat, poultry, fish, seafood, and related products. These belts prioritize food regulation compliance, sanitary and hygienic properties, and the prevention of product contamination. Following hygienic design principles, Newtop’s belts are designed to eliminate areas where bacteria and contaminants could accumulate, allowing thorough cleansing with water across all belt surfaces for optimal food safety.

Bakery and Confectionery

NewtopLINK for

bakery and confectionery

Bakery products vary widely, from large loaves of bread to small, intricately shaped biscuits. Whatever your specific product, managing tight transfers and ensuring smooth product release from the belt can be challenging. Newtop offers a comprehensive range of plastic modular belts designed to meet all the needs of the bakery and confectionery industry.

Tire Industry

NewtopLINK for

tire manufacturing

The tire production process involves various stages, from rubber mixing to creating the green tire and producing the final product. Newtop provides a broad array of solutions to support each step of this process.

Automotive Industry

NewtopLINK for

car assembly lines

The tire production process involves various stages, from rubber mixing to creating the green tire and producing the final product. Newtop provides a broad array of solutions to support each step of this process.

Specialized product lines in the NewtopLINK range

Newtop Engineering has developed product lines tailored to meet the specific needs of the industries we serve. Our solutions range from ensuring food safety and hygiene to handling delicate products and facilitating tight transfers, as well as features designed to enhance maintenance and streamline belt installation.

Newtop Super NyCLEAN

Newtop Engineering’s Super NyCLEAN products are specifically designed for applications that demand the highest hygienic standards, particularly in poultry and fish processing.

Newtop NyCLEAN

Browse the NewtopLINK product range

Newtop SeleCalc is an advanced engineering program supporting belt selection

Ready for industry challenges

Impact resistance

Plastic modular belts must be able to withstand impacts on their top surfaces. While standard plastic materials generally provide good overall resistance under these conditions, some heavy-duty applications require specialized solutions to ensure the belt remains fully operational and to prevent unwanted downtime. Newtop LINK plastic modular belts offer a wide variety of specific solutions designed to enhance the belts’ resistance to product impacts on the surface.

Chemical resistance

In food applications, belt sanitation is essential for meeting customer safety requirements. To uphold high safety standards, all equipment and belts must be thoroughly cleaned with aggressive detergents and then rinsed completely. Newtop LINK materials provide exceptional resistance to the cleaning agents commonly used in the food industry. Certain industrial processes can be particularly harsh on plastic materials. One of the most aggressive environments is found in the filling, testing, charging, and handling of car batteries, which contain sulfuric acid.

Wide temperature range

To maintain food properties and extend shelf life, several key industrial processes involve freezing products. Product freezing typically requires ambient temperatures around -35°C or lower. To meet these demanding conditions, Newtop LINK modular belt ranges offer material solutions that perform effectively within this temperature range. The food-compliant material POM is commonly used for freezing applications down to -40°C. For even more extreme freezing processes, the PE material can operate at temperatures as low as -70°C.

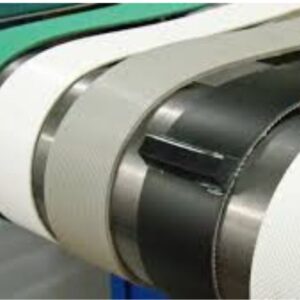

Tight transfers

Transferring products from one conveyor to another can be challenging, especially when dealing with light, small-footprint, and unstable items. As the transfer diameter decreases, the passage becomes more critical. For very small product transfers, fabric belts are often used because they enable small knife-edge transfers. However, in many cases, this solution may not be feasible due to concerns such as belt tracking, potential belt slippage, and application conditions that do not permit the use of fabric belts.