Conveyors are the backbone of countless industries, from mining and manufacturing to packaging and logistics. They ensure smooth operations, reduce manual labor, and boost productivity. But like any machine, they experience wear and tear over time. That’s why belt conveyor repair and preventive maintenance are crucial for avoiding downtime and maximizing efficiency.

At Newtop Engineerings, we specialize in offering reliable solutions that extend the life of conveyor systems. In this article, we’ll cover the essentials of belt conveyor repair, routine maintenance strategies, and expert practices to ensure your system delivers consistent performance year after year.

Why Belt Conveyors Fail

Understanding the common causes of conveyor issues helps in preventing expensive breakdowns. Here are the most frequent culprits:

- Material Spillage – Excess material buildup on pulleys or rollers can cause belt misalignment.

- Wear and Tear – Continuous friction leads to worn belts and damaged rollers.

- Poor Tensioning – Incorrect tension shortens belt life and reduces efficiency.

- Misalignment – Off-center belts increase friction and may damage both the belt and the structure.

- Lack of Lubrication – Dry bearings or pulleys generate heat and lead to breakdowns.

Addressing these issues early can prevent the need for costly replacements.

Signs That Indicate the Need for Repair

Before catastrophic failure occurs, conveyors often display warning signs. Watch for:

- Frequent belt slippage

- Unusual noise or vibration

- Uneven material flow

- Increased energy consumption

- Visible cracks or fraying edges

If you notice these symptoms, immediate belt conveyor repair is essential.

Best Practices for Maintenance and Longevity

1. Conduct Regular Inspections

Schedule routine checks to monitor belt alignment, tension, and surface conditions. Early detection of small problems reduces the likelihood of major breakdowns.

2. Clean and Remove Material Build-up

Debris left on the conveyor can damage rollers, pulleys, and even the belt itself. A clean system is more efficient and less prone to unexpected issues.

3. Lubricate Moving Parts

Bearings, pulleys, and rollers should be lubricated according to manufacturer recommendations. Proper lubrication minimizes friction and extends component lifespan.

4. Maintain Correct Tension

Too much tension causes stress on splices and bearings; too little leads to slippage. The correct balance ensures smooth operation.

5. Align the Belt Properly

Misaligned belts not only reduce efficiency but also cause wear on edges. Regular adjustments keep belts running straight and true.

6. Replace Worn Parts on Time

Don’t wait for a part to fail completely. Proactive replacement of worn rollers, bearings, or belt sections prevents unplanned downtime.

7. Train Your Workforce

Operators and maintenance staff should be trained to detect early warning signs and follow safety procedures during inspection and repair.

Professional vs. In-House Repairs

While some minor adjustments can be handled in-house, more complex issues require professional expertise. For example:

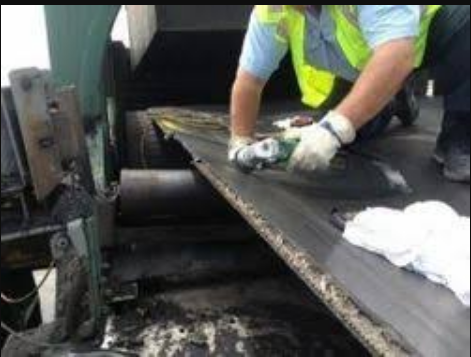

- Pulley lagging replacement

- Major splice repairs

- Structural realignment

- Complete belt replacement

Partnering with experts like Newtop Engineerings ensures repairs are performed correctly, quickly, and safely, minimizing downtime.

How Newtop Engineerings Helps Extend Conveyor Life

At Newtop Engineerings, we combine years of hands-on experience with innovative solutions. Our services include:

- On-site inspection and troubleshooting

- Emergency repair services

- Customized maintenance programs

- Supply of durable spare parts

- Expert guidance for preventive care

Our mission is to help businesses achieve maximum uptime, reduce operational costs, and ensure safety across all conveyor systems.

Safety Considerations During Repair

Safety should always come first. Follow these guidelines during repair or maintenance:

- Lock out and tag out equipment before working

- Wear appropriate protective gear

- Never bypass safety guards

- Ensure only trained personnel carry out repair work

- Conduct a post-repair test before resuming full operation

These steps not only protect workers but also guarantee the repair process restores the conveyor to optimal performance.

Benefits of Regular Maintenance

Investing in a consistent maintenance schedule delivers long-term advantages:

- Reduced unplanned downtime

- Lower energy consumption

- Improved product quality

- Extended equipment lifespan

- Greater workplace safety

Businesses that prioritize maintenance often see significant cost savings over time.

Final Thoughts A well-maintained conveyor system is an asset that drives efficiency and reliability in any operation. By following best practices and partnering with trusted experts like Newtop Engineerings, you can ensure smooth operations and extend the lifespan of your equipment.