Car Assembly

Dependability in the automotive assembly industry.

Newtop Engineering is the robust partner you need for your high-volume, high-quality automotive assembly applications. With a focus on wear and impact resistance, safety, reliability, and low maintenance, we provide solutions to tackle your most demanding challenges.

Customers around the globe trust Newtop Engineering for our extensive industry expertise and customized solutions utilizing high-performance belts tailored to a variety of processing requirements and applications. Antistatic belt materials are available for facilities where operators come into contact with the belt’s surface, while non-slip finishes ensure safe movement for operators.

We offer the perfect solution for your challenges.

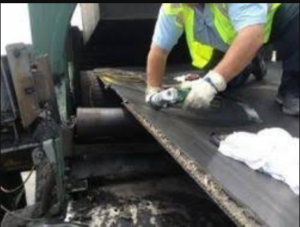

Low machine downtime and maintenance

Plastic modular belts are simple to maintain and quick to repair due to their modular design and lightweight structure. In skid conveyor applications, low-friction, silicone-free materials eliminate the need for lubrication, resulting in lower power consumption, reduced noise levels, and extended belt lifespans.

Wear resistance

Durable wear- and impact-resistant belting solutions can endure the most challenging applications in the automotive assembly industry, providing minimized belt downtime and extended belt lifespan.

Heavy load-carrying capability

High-strength materials guarantee that our belts can reliably transport even the heaviest loads. Specifically designed for the industry, they ensure the safe and secure conveyance of heavy passenger vehicles and individuals.

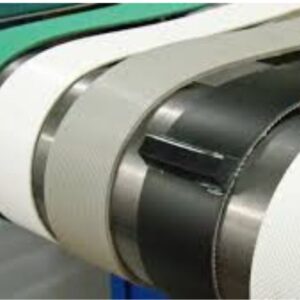

Impact resistance

Cuts and scratches can harm the belt and shorten its lifespan. Newtop Engineering belts utilize impact-resistant materials that enhance the belt’s durability, even in metal stamping applications.

Looking for the best solution for your

application?

Featured products

Newtop Engineering provides solutions throughout the tire manufacturing process.