Insulation

Refined solutions for stone applications

Insulation processing machines demand a diverse range of industrial belting. Newtop Engineering’s broad selection of conveyor and processing belts allows us to provide the ideal belting solution for every manufacturing application, whether it’s for glass wool, rock wool, or engineered insulation

Through years of close collaboration with leading original equipment manufacturers, insulation product suppliers, and industry specialists, Newtop Engineering has developed the specialized expertise and high-quality products to meet your most demanding requirements. We are pleased to offer expert consulting in all areas of insulation material manufacturing.

We offer the perfect solution for your challenges.

Easy release

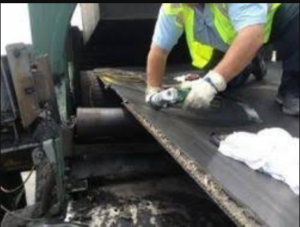

In mineral and glass wool production, strong and reliable belt joining is crucial, as wool fibers can get beneath the belt and cause excessive longitudinal tension. Newtop Engineering provides robust and reliable joining solutions for belts used in glass and wool processing, ensuring they withstand even high tensile stress.

Strong and reliable belt joining

In mineral and glass wool production, strong and reliable belt joining is critical, as wool fibers can get beneath the belt and create excessive longitudinal tension. Newtop Engineering offers durable and dependable joining solutions for belts used in glass and wool processing, ensuring they withstand even high tensile stress.

Flame-retardance

Newtop Engineering belts used at the “Hot End” are equipped with ATEX conformity and flame-retardant certification, such as ISO 340 or UL 94HB, depending on regional and customer requirements. We understand the challenges posed by hot magma “spots” that can drop onto belts, which is why our belts are designed to be self-extinguishing.

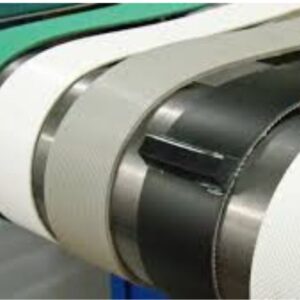

Abrasion and wear resistance

Glass and rock wool dust create a highly abrasive environment, causing belt surfaces to wear over time due to abrasion from hard particles or mechanical cleaning processes. Newtop Engineering belts are made from abrasion-resistant materials suitable for all types of applications, extending the average lifespan of the belt.

Custom fabrication

Glass and rock wool blanket manufacturing requires belts that are wider than those used in many other industries. Newtop Engineering provides specialized solutions for various applications, including longitudinal splices, sewn mechanical splices, and reinforced edges, meeting all the demands of the manufacturing processes in the insulation industry.

Temperature resistance

The operating environment for rock wool and glass wool production ranges from ambient temperatures at the “Cold End” to extremely high temperatures at the “Hot End.” Newtop Engineering belts deliver exceptional performance across the full spectrum of operating temperatures, from minimum to maximum.