Wood

Robust and adaptable solutions for the wood industry

Wood processing machines need a diverse array of industrial belting. Newtop Engineering’s extensive range of power transmission, conveyor, and processing belts guarantees the optimal solution for every application. Whether for solid wood processing, industrial furniture manufacturing, or production lines for engineered wood products such as particle board, MDF/HDF, OSB, plywood, and LVL, you can trust us to provide the best belting solution for your needs.

Our close collaboration with leading original equipment manufacturers, wood products suppliers, and industry specialists has enabled Newtop Engineering to develop the technical expertise and specialized belting products needed to meet your most demanding requirements. We are pleased to offer consulting services for all aspects of wood-based manufacturing.

We offer the perfect solution for your challenges.

Easy release

Wood boards made from chips and fibers tend to be very sticky, which is why Newtop Engineering belts offer excellent release properties. This ensures the belt surface stays clean, sticky products are transferred without deformation, and boards are produced with outstanding surface consistency and quality.

Chemical resistance

To handle the adhesives and release agents commonly used in the wood industry, Newtop Engineering belts are designed with high chemical resistance. This prevents belt layer delamination and ensures a longer belt lifespan.

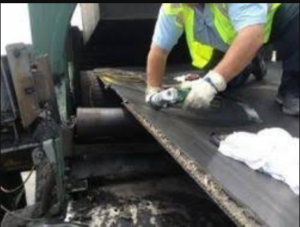

Efficiency and safety

Newtop Engineering belts can be supplied with fast installation options, such as DLS (double loop seam) or SLS (single loop seam), enabling customers to install the belts themselves. To meet the fire safety requirements of the wood industry, all our belts come with ATEX conformity. Additionally, our belts are designed for easy cleaning.

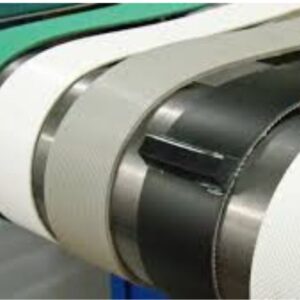

Abrasion and wear resistance

Wood dust, chips, and fibers create a highly abrasive environment, and belt surfaces can deteriorate over time due to abrasion from hard particles or mechanical cleaning. Newtop Engineering belts are made from abrasion-resistant materials designed for all types of applications, ensuring a longer belt lifespan.

Clogging-free solution

To address the issue of clogging in the board manufacturing process, especially in deaeration and pre-heating applications, Newtop Engineering provides a premium polyester wire mesh belt with a clogging-resistant design. It is also ideal for small pulleys, enabling tight and precise transfers.

Temperature resistance

Operating environments in the wood industry can range from ambient temperatures in bunker applications to extremely high temperatures before the continuous press. Newtop Engineering belts deliver outstanding performance across this entire range of operating temperatures.