Bakery and

Confectionery

The right solutions for bakery and confectionery processing

You can rely on expert technical advice from Newtop Engineering, along with the best solutions tailored to your application needs. Whether it’s handling dough, cooling baked goods, molding, cutting, or packaging, Newtop Engineering provides a comprehensive range of products and services for the bakery and confectionery processing industry, including bakery conveyor belts.

Our specialized solutions offer high resistance to oil and fat, superior wear resistance, extended service life, and enhanced performance of bakery conveyor belts, all while minimizing the risk of fiber contamination. At Newtop Engineering, we understand the complexities of increasing hygiene standards and food compliance in the industry, ensuring you can count on us for safe and trouble-free food production.

We have the right answer for your challenges

Temperature resistance

The operating conditions in the bakery and confectionery industry can fluctuate from extremely high temperatures during the baking process to very low temperatures during cooling and freezing phases. This requires belts that can perform effectively across a broad temperature range. Newtop Engineering ensures that our belts operate continuously and efficiently, meeting the necessary performance standards at both minimum and maximum temperatures.

Resistance to fat and oil

In the bakery and confectionery industry, oils and fats are prevalent. That’s why Newtop Engineering has tailored our products for this sector, using materials that are highly resistant to oils, fats, and the cleaning chemicals involved. By preventing cracking and delamination of belt layers due to oils and fats, our belts offer extended lifespans and reduce the risk of contamination.

Efficient cleaning and sanitation

Due to the significant buildup of oils, fats, salt, and dough residue on belt surfaces, it is crucial that they are easy to clean to comply with today’s stringent hygiene standards. With the increasing use of aggressive detergents, Newtop Engineering belts are designed to provide exceptional chemical resistance and enhanced sanitation. The materials and construction of our belts are specifically developed to simplify the cleaning process and maintain superior hygiene.

Gentle handling of small and delicate products

Belting in bakery and confectionery applications must ensure smooth and precise transfers to prevent product deformation as it moves from one belt to another. To address this challenge, Newtop Engineering offers belts with high longitudinal flexibility, ideal for use with nosebars and knife edges, ensuring tight and accurate transfers.

Easy release

Bakery and confectionery products are often quite sticky due to doughs containing oils, fats, sugars, and coatings like chocolate or cream, which can adhere to the belt surface. Newtop Engineering provides the perfect solution for handling sticky products: belts with superior release properties that not only keep the belt surface clean but also transfer sticky items without causing deformation or contamination.

Abrasion resistance

In the bakery, biscuit, and pasta industries, the heavy use of salt, sugar, flour, and spices creates an abrasive environment. Over time, belt surfaces can degrade due to wear from hard particles. Additionally, mechanical cleaning with metal scrapers or hard plastics can cause grooves or superficial cracks, which may promote mold or bacterial growth. Newtop Engineering offers belts with abrasion-resistant surfaces that are suitable for various applications, ensuring longer belt lifetimes and enhanced durability.

Low risk of contamination and cross-contamination

Contamination risks can severely impact your bakery and confectionery products during processing, especially in the fresh dough handling stages, potentially resulting in major production losses. Newtop Engineering’s belting solutions are designed for maximum reliability, offering excellent abrasion resistance, easy cleaning, and long-lasting durability. Our materials and designs are crafted to prevent bacterial contamination, ensuring both the safety of your products and the protection of your brand’s reputation.

Looking for the best solution for your

application?

Featured products

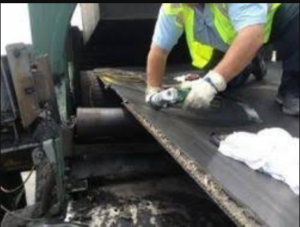

Belt Conveyor Repair Made Easy: Best Practices for Maintenance and Longevity

The Benefits of Partnering with a Reliable Conveyor Solutions Provider

How Belt Conveyors Revolutionize Food Processing and Packaging

Downloads