Fish and Seafood

Conveyor Belts for the Fish Industry

Efficient operation for fish and seafood processing

Superior hygiene standards, food compliance, and precision are essential in the fish and seafood industry.

At Newtop Engineering, we fully understand these demands and offer a comprehensive range of fish processing belting solutions to meet your every requirement. Our products feature advanced hygienic designs, excellent release properties, and precise positioning — all while minimizing waste.

Whether you require technical support for a specific application or a custom belting solution to address a unique challenge, our dedicated industry experts are ready to provide tailored recommendations to meet your most stringent needs.

We offer the perfect solution for your challenges.

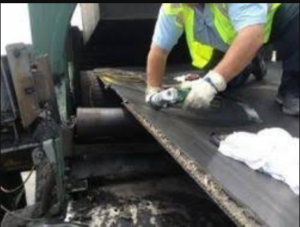

Efficient cleaning and sanitation

The fish, shrimp, and crab industry requires regular cleaning with strong cleaning agents. Newtop Engineering incorporates highly efficient hygienic designs and premium molding to ensure cleaning is quick, easy, and effective. Our chemical-resistant materials allow you to clean the belts thoroughly without reducing their lifespan.

No marking of the products

Non-marking properties are essential for belts in this industry to ensure the product remains undamaged. To prevent any marks on the products, Newtop Engineering offers a wide range of flush grid belts with rounded, blunt edges, along with flat top belts and round bars on flights, all designed to protect your products from damage.

Good friction properties

Newtop Engineering belts, with superior friction properties, are ideal for applications where products need to remain stationary on the belt. We also provide a wide selection of flights for incline and bulk conveyors, tailored to meet your specific needs.

Good water drainage

During thawing, grading, cooling, and glazing processes, effective water drainage is crucial. Newtop Engineering provides belting with a flush grid surface, specifically designed for wet environments to ensure optimal drainage.

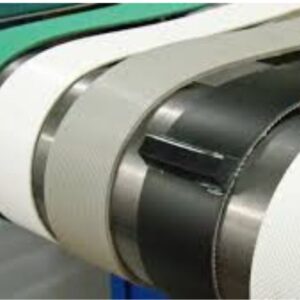

Precise positioning

In certain applications, it is essential that products reach the right location at the right time. Newtop Engineering offers sprocket-driven belts, including modular belts, Cleandrive belts, and timing belts, which ensure precise positioning without slippage.

Low risk of contamination and cross-contamination

Any contamination can damage your products, resulting in costly waste and production losses. Newtop Engineering’s hygienic designs and easy-to-clean belts help prevent contamination in your applications, ensuring your products remain consistently and reliably safe.

Good release

Certain applications in this industry require excellent product release properties. Newtop Engineering uses carefully designed belt materials and surface structures to meet this need across a wide range of applications.

Wear resistance

Scratching and abrasion from hard shells can damage belting, with components like pins wearing down quickly due to contact with the top shell. As a result, durability is essential in many applications. Newtop Engineering offers wear-resistant materials that ensure long belt lifetimes without elongation.

Featured products

Explore product lines that deliver proven performance in fish and seafood processing.