Secondary Packaging

Providing the solutions you need for Secondary Packaging

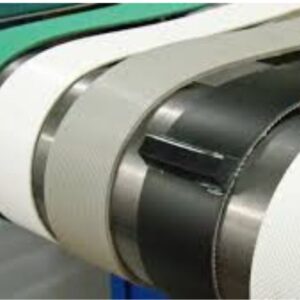

Secondary packaging demands efficient processing to safeguard both the product and its primary packaging. We can assist you in selecting the optimal conveyor and processing belts to enhance process efficiency, boost productivity, and reduce maintenance costs.

Newtop Engineering not only helps you find the ideal belting solution but also offers a range of services beyond belting, including technical support and consultancy. With a focus on high-speed performance and precise positioning, we deliver solutions designed to meet your most demanding applications.

We offer the perfect solution for your challenges.

Excellent high-speed performance

In cartoning applications, the high speed of the line can pose a challenge. Newtop Engineering provides outstanding solutions for high-speed applications on various packaging machines, while enabling the use of low-friction materials.

Precise positioning

Precise positioning during product handling is essential; the product must remain in the exact expected position. Newtop Engineering ensures that your products stay properly positioned, preventing damage to packaging and avoiding product logjams or line blockages.

Reduced machine downtime and maintenance

Minimizing unscheduled production stoppages is a key challenge. Newtop Engineering’s highly reliable belts reduce the risk of unexpected breakages. For instance, belts that don’t require re-tensioning help lower downtime and simplify maintenance, ensuring consistent performance over time.

Temperature resistance

During the shrinking process in wrapping and bundling applications, high heat can damage unsuitable belt materials. That’s why Newtop Engineering offers belt materials specifically designed for high-temperature film packing applications, including over-wrapping, shrink packaging, and hot melt adhesive processes.