Paper Printing and

Finishing

A comprehensive range of solutions for paper printing and finishing

Newtop Engineering’s belting solutions deliver the results you need in the paper printing and finishing industry. From quick and easy belt installation to reliable operation and high performance, we support you at every stage of the paper printing and finishing process.

Our premium-quality belts ensure precise processing, excellent paper handling, and long-lasting durability. You can rely on our technical expertise at every step to help you make the best choices tailored to your specific needs.

We offer the perfect solution for your challenges.

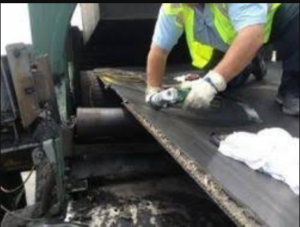

Reduced machine downtime and maintenance

Newtop Engineering’s top-quality belting prevents unplanned downtime and ensures high productivity throughout its lifetime. Excellent abrasion resistance and dimensional stability support long belt lifetimes and optimal performance. The combination of superior flex-fatigue properties and robust materials also helps minimize downtime.

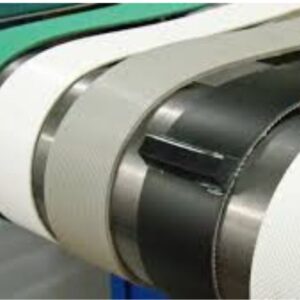

Stable speed

Maintaining a stable speed is crucial in the paper industry to ensure precise printing, folding, and processing of paper. A secure and consistent grip throughout the entire belt lifetime guarantees reliable load transmission and process accuracy, even at high speeds.

High abrasion resistance

High wear and abrasion in paper printing and finishing lines can be challenging, but our belts, made from highly robust and durable materials, are up to the task. Exceptional abrasion resistance and dimensional stability ensure optimal belt performance with minimal machine downtime. Combined with excellent flex-fatigue properties, these features contribute to industry-leading belt lifetimes from Newtop Engineering.

Operational in challenging ambient conditions

We ensure that your processes operate smoothly, even in the most challenging environmental conditions. Our durable belt materials from Newtop Engineering are designed to withstand high temperatures and humidity. They offer excellent dimensional stability, even with fluctuating ambient humidity, eliminating the need for re-tensioning and ensuring optimal performance with minimal downtime.

No smearing and marking of the paper

Newtop Engineering solutions provide the ideal surface properties for every type of paper being conveyed. Our belts offer a secure, smooth, and consistent grip throughout their entire lifetime, ensuring precise and reliable processing and transport of paper without causing marks, scratches, or smears.

High precision of process

Newtop Engineering belts maintain a consistent coefficient of friction, ensuring reliable conveying throughout the entire belt lifetime and preventing paper slippage.

Reliable operation in sticky environment

Newtop Engineering ensures flawless operation in adhesive-heavy environments, providing stable transportation of freshly glued products, such as those using hot glue in bookbinding machines.

Good tracking of the paper web

Newtop Engineering belts offer accurate tracking and precise positioning, ensuring paperboard and paper sheets are cut with the utmost precision during transportation.

Anti-static properties

Resistance to heavy dust

In paper printing and finishing processes, the environment can become very dusty due to paper dust generation. Belts exposed to heavy dust are at risk of abrasion. Newtop Engineering belts are highly abrasion-resistant, offering best-in-class longevity even in these challenging conditions.