At Newtop Engineerings, we specialize in manufacturing high-quality power transmission belts that ensure efficient and reliable power transfer across various industrial applications. Whether you need power transmission belts for automotive, manufacturing, agricultural, or heavy machinery, our premium range is designed to deliver unmatched durability and performance.

Why Choose Our Power Transmission Belts?

Our power transmission belts are engineered with cutting-edge technology and superior materials to provide optimal efficiency. Here’s why industries trust Newtop Engineerings:

- High Durability: Made from top-grade rubber, synthetic polymers, and reinforced materials to ensure a long service life.

- Superior Flexibility: Designed to withstand high mechanical stress and adapt to different operational conditions.

- Energy Efficient: Reduces friction, enhances performance, and minimizes energy loss.

- Customizable Solutions: Available in various sizes, materials, and configurations to meet specific industrial needs.

- Low Maintenance: Our power transmission belts require minimal upkeep, saving both time and costs.

Types of Power Transmission Belts We Offer

At Newtop Engineerings, we provide a wide range of power transmission belts to cater to different industries. Our selection includes:

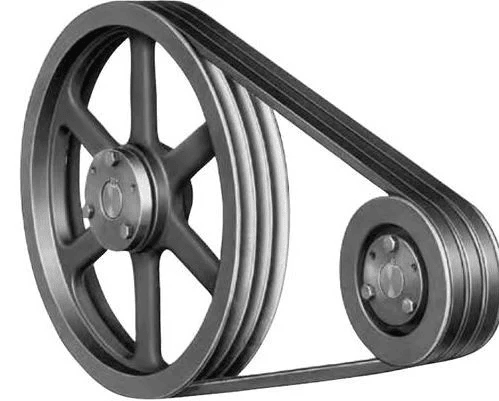

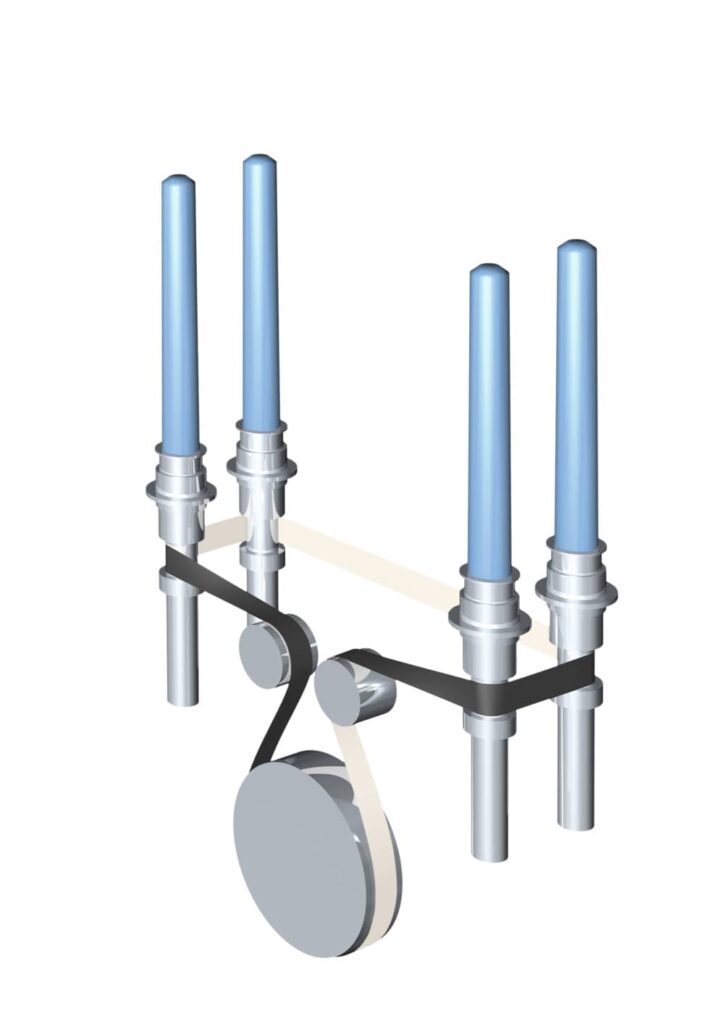

1. V-Belts

V-belts are among the most commonly used power transmission belts, offering high efficiency and reliability in various applications. They are perfect for industrial machinery, automotive engines, and heavy-duty equipment.

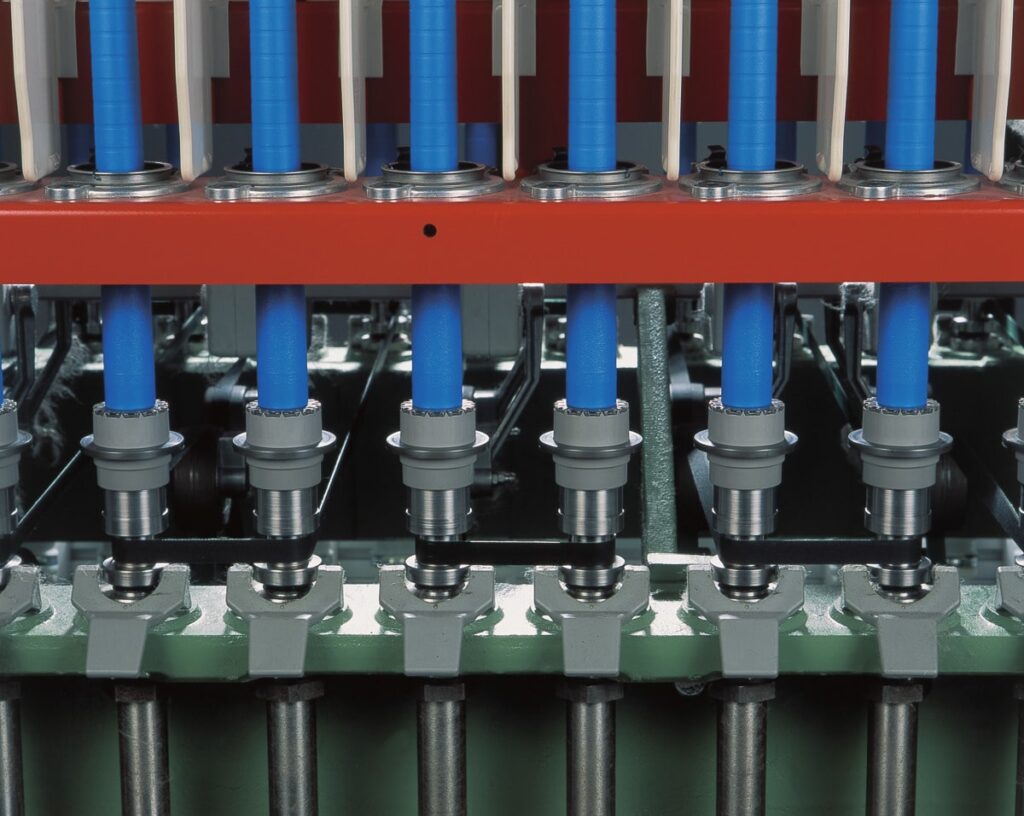

2. Timing Belts

Timing belts ensure synchronized movement in mechanical systems. These power transmission belts are essential for precision-driven operations, including conveyor systems, automation machinery, and internal combustion engines.

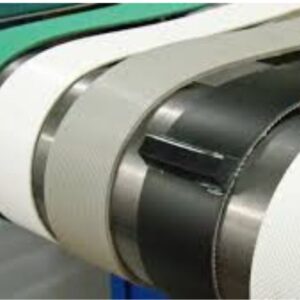

3. Flat Belts

Flat belts are ideal for high-speed and low-torque applications. They are widely used in textile mills, paper industries, and packaging plants due to their smooth operation and excellent power transmission capabilities.

4. Poly V-Belts

Poly V-belts, also known as ribbed belts, combine the benefits of flat and V-belts, providing high efficiency and enhanced durability. They are extensively used in automotive and heavy machinery applications.

Industries That Rely on Our Power Transmission Belts

Our power transmission belts serve a diverse range of industries, ensuring efficiency and reliability in multiple sectors:

- Automotive Industry: Used in engine components, cooling systems, and alternators.

- Manufacturing Plants: Drives conveyor belts, assembly lines, and production machinery.

- Agriculture: Essential for tractors, harvesters, and irrigation systems.

- Textile Industry: Powering looms and fabric processing machines.

- Food Processing: Maintaining hygiene and efficiency in automated food packaging and production.

Benefits of Using Newtop Engineerings’ Power Transmission Belts

Choosing our power transmission belts comes with numerous advantages:

- Increased Operational Efficiency – Our belts enhance productivity by ensuring seamless power transfer with minimal energy loss.

- Cost-Effective Solutions – With reduced maintenance and extended lifespan, our belts offer the best return on investment.

- Custom Engineering – We provide tailored solutions to meet specific operational needs, ensuring maximum compatibility and performance.

- Eco-Friendly Manufacturing – Our production process adheres to sustainable practices, reducing environmental impact while maintaining quality.

How to Select the Right Power Transmission Belts

Selecting the ideal power transmission belts depends on several factors:

- Load Capacity: Assess the required load-bearing capacity for efficient performance.

- Speed Requirements: Choose belts that match the speed and torque of your machinery.

- Environmental Conditions: Consider temperature, humidity, and exposure to chemicals or abrasives.

- Belt Material: Opt for materials that provide durability and longevity under operational stress.

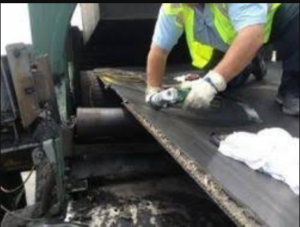

Maintenance Tips for Power Transmission Belts

To maximize the lifespan and efficiency of your power transmission belts, follow these maintenance practices:

- Regular Inspections: Check for wear, cracks, or misalignment to prevent sudden failures.

- Proper Tensioning: Ensure belts are neither too tight nor too loose to maintain optimal performance.

- Clean Belts & Pulleys: Remove dirt, oil, or debris to avoid premature wear and tear.

- Lubrication & Cooling: Apply recommended lubricants and ensure proper ventilation for heat dissipation.

Get the Best Power Transmission Belts from Newtop Engineerings

At Newtop Engineerings, we are committed to providing top-notch power transmission belts that enhance productivity and efficiency in various industrial applications. Our products undergo rigorous quality control to ensure they meet industry standards and customer expectations. Upgrade your machinery with our premium power transmission belts today! Contact Newtop Engineerings for customized solutions and expert guidance.