Accessories

Expanding the versatility of belt performance

Conveyor and processing belts operate within complex and varied processes. The reliability of their joining methods, along with the option to equip them with high-quality accessories, adds significant value and ensures optimal support for every application. Newtop’s solutions are designed to enhance performance and meet the highest standards in process efficiency.

Newtop has developed an extensive range of belt accessories and conveyor components designed to enhance belt performance and offer precise customization to meet your specific process needs.

Belt Accessories

Profiles and cleats

Depending on the type of product being processed, line optimization and conveying efficiency may demand a high degree of belt customization. Newtop’s range of belt accessories—including tracking guides, cleats, sidewalls, and flat profiles for edge sealing—ensures you’ll find the ideal solution to meet your specific requirements.

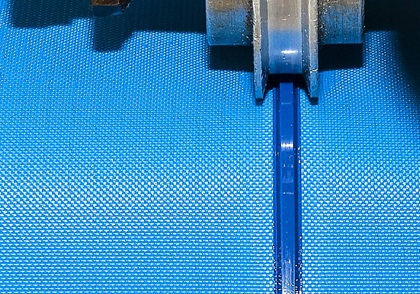

Tracking guides

Tracking guides are positioned on the running side of conveyor belts or on the tooth side of timing belts to ensure accurate belt tracking in applications that utilize long, narrow belts for product conveyance. They are also commonly used in situations where products are side-loaded, which could otherwise lead to a lateral shift in the belt’s direction of travel. The tracking guides can be notched or deep notched to offer maximum flexibility around the pulleys. Newtop provides these essential components to enhance your conveyor systems.

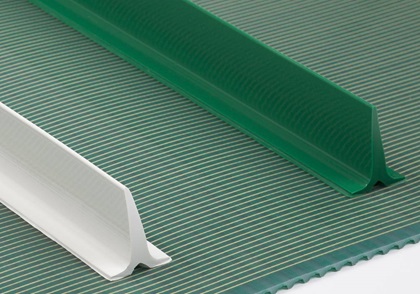

Cleats

Thermoplastic profiles and cleats are mainly used in incline or decline transport, where they aid in conveying and precise product placement. Newtop’s advanced fabrication processes ensure hygienic edges, making them especially suitable for applications in the food industry.

Sidewalls

Corrugated sidewall profiles from Newtop support diverse applications, from food processing to materials handling. These sidewalls can be used with or without cleats, offering excellent flexibility and high wear resistance for a long service life and exceptional performance. They are primarily used to contain bulk goods efficiently.

Edge sealing

Edge sealing is an additional hygiene measure mostly found in food applications to protect the inner layer of coated fabric belts from soiling by liquids or contamination by microorganisms. Edge sealing can also be applied to avoid fiber contamination of products, machines or bearings.

Wave profiles

Wave profiles are highly effective in fruit and vegetable processing, providing gentle product handling and essential shock absorption. These profiles act as shock absorbers on both flat and slightly inclined surfaces, making them ideal for delicate produce. Newtop wave profiles are also certified for direct food contact, ensuring safety and efficiency in food processing applications.

Accessories materials

TPO

TPO profiles, cleats, and edge sealing are widely used in food processing due to TPO’s excellent release and chemical resistance properties. These accessories can be cleaned thoroughly with detergents, making them easy to maintain and ideal for high-hygiene environments. Newtop’s TPO components ensure optimal food safety and cleanliness in processing applications.

TPU

Newtop’s thermoplastic polyurethane (TPU) profiles and cleats are ideal for applications involving small pulley diameters. With high bending fatigue strength and flexibility—even in low temperatures—they offer superior chemical and abrasion resistance. Most of Newtop’s TPU profiles comply with food safety regulations, making them suitable for handling unpacked foodstuffs and easy to clean for optimal hygiene in processing environments.

PVC

Newtop’s polyvinyl chloride (PVC) profiles and cleats offer high flexibility and robust chemical resistance, making them ideal for a wide range of applications, especially in wet environments.

TPEE

Newtop’s thermoplastic copolyester elastomer (TPEE) profiles offer excellent abrasion and chemical resistance, along with high dimensional stability, making them ideal for use in wet environments. TPEE profiles are primarily used with TPEE conveyor and processing belts, commonly in the tobacco industry and select food applications.

Find out more about belt

engineering and customization

technical expertise and state-of-the-art equipment, we achieve results that go beyond standard

fabrication, meeting even the most demanding market needs.