Conveyor Chains

Flexible chain solutions for every need

Reliable and cost-effective chain conveyor solutions are essential in various applications across multiple industries. The Newtop Engineering HabaCHAIN range offers over 60 different types of high-quality chains, including straight-running and radius/side-flexing options. Fully compatible with industry standards, our chains can run on most systems and sprockets available today, making retrofitting easy without the need for conveyor modifications.

Newtop HabaCHAIN products are offered in a wide array of problem-solving materials, providing key features such as low friction, enhanced chemical resistance, high-temperature resistance, and anti-static and magnetic properties. The industries we serve include automotive, bakery, beverage and canning, materials handling, meat, poultry, and fish, packaging, pharmaceuticals, snack foods, textiles, and tissue.

Features and benefits

The innovative Newtop Engineering HabaChain range offers a comprehensive set of valuable features and benefits:

- High tensile strength for reduced downtime and optimized conveyor line layouts

- World-class quality for superior product handling

- Low friction materials for excellent performance in high-speed applications

- Bevel edges to ensure product stability during multiple-strand conveying

- High friction inserts for specialized product conveying solutions

- Wide selection of special materials to meet all your application needs

Product Types

The Newtop HabaCHAIN range delivers optimal solutions through its extensive selection of product types:

- Slat top plastic and steel chains

- Low back pressure (LBP) chains

- Flexi chains

- Snap-on chains

- Multiflex chains

- Case chains

We also offer a complementary range of sprockets, idlers, and inserts.

NewtopCHAIN Range

Straight Chains

Straight chains are primarily utilized in the food and packaging industries for conveying packed products, bottles, and cans. They are available in a diverse selection of materials and designs, including:

- Slat top chains (plastic)

- Slat top chains (steel)

- Low back pressure (LBP) chains equipped with small rollers for low-pressure case accumulation

- Snap-on flat top chains (based on carbon or stainless steel roller base chains)

- Case chains, primarily for case handling (includes a connecting link accessory)

Radius Chains

Radius chains are widely used in the food and packaging industries to transport packaged goods, bottles, and cans efficiently. Available in various materials, they come in tab, bevel, or magnetic designs tailored to specific needs.

- Slat Top Chains (Plastic)

- Slat Top Chains (Steel)

- LBP Chains – Equipped with small rollers to enable low-pressure case accumulation

- Snap-On Chains – Flat top chains, also available with rubber inserts, featuring a carbon or stainless steel roller base chain

- Flexi Chains – Highly flexible radius chains ideal for modular conveyor systems

- Case Chains – Designed specifically for case handling

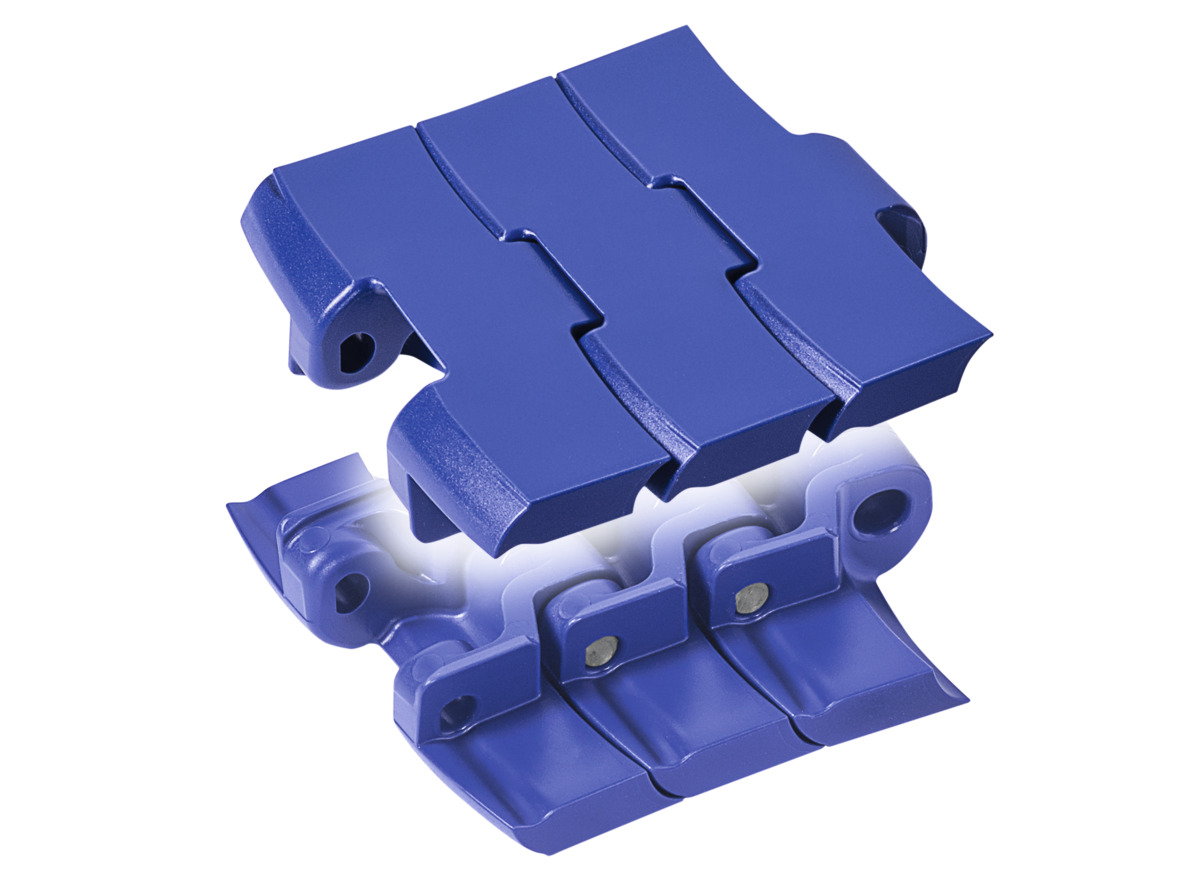

- Multiflex Chains – Heavy-duty, bi-planar plastic chains for inclined conveyors with a minimal radius

Newtop Engineering offers these specialized radius chains, designed to enhance efficiency and meet the diverse demands of the food and packaging industries.

Materials

Newtop Engineering’s chains are crafted from the highest-quality plastic materials, aligned with our commitment to delivering optimal solutions for your needs. We ensure the best material choice to match your application requirements. Below are some of the materials we offer:

- Standard POM – Offers good strength and an excellent coefficient of friction, ideal for standard or low-speed applications

- Low-Friction POM – High strength with good abrasion resistance, suited for high-speed, food-contact-approved applications

- Enhanced Low-Friction POM – Features a low coefficient of friction, high strength, and good abrasion resistance, optimal for high-speed applications with minimal lubrication

- Extra-Low-Friction POM – Contains specialized self-lubricating agents, providing the lowest friction values and supporting the highest load and speed limits

- Extra-Low-Friction PBT – Strong with exceptional abrasion resistance, ideal for high-speed, dry-running applications

- Carbon Steel and Stainless Steel – Suitable for heavy-duty and abrasive environments

Specialty Materials

We also provide an array of specialty materials that offer added benefits such as extra strength, enhanced wear resistance, low electrical surface resistance, metal or X-ray detectability, and high chemical resistance.

Saniclip link for

Case Chain

1201AB

The Case Chain 1201AB Saniclip Link from Newtop Engineering provides a quick and efficient method for chain assembly and disassembly.

This link is specifically engineered for highly demanding sanitary environments where frequent chain removal is necessary for cleaning. It minimizes downtime during maintenance, making operations more efficient.

Removing the pin is straightforward; simply rotate the external lever, secured by a clip, using a common tool (such as a screwdriver), and pull the pin out by hand.

The Saniclip pin design prevents potential chain damage or reduction in pin retention force due to improper handling during insertion and removal. The link’s distinctive yellow color allows for easy identification within the chain.