Fabric Belts

Premium Swiss-quality fabric belts with world class performance.

Every Newtop Engineering solution is crafted with exceptional precision, establishing performance benchmarks in the belting industry. We guarantee the reliability and adaptability of our solutions by combining premium raw materials with cutting-edge manufacturing techniques and our extensive engineering expertise.

Fabric Belts

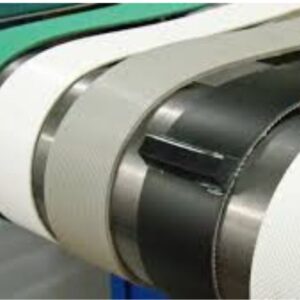

Light Conveyor Belts

Newtop Engineering’s light conveyor belts feature a plied construction and offer a wide range of design options, making them a reliable choice for nearly all materials handling and processing industry applications, including high-tech automation. They can be made flexible to handle small pulley diameters or stiff for the demands of heavy industries. The possibilities are virtually limitless.

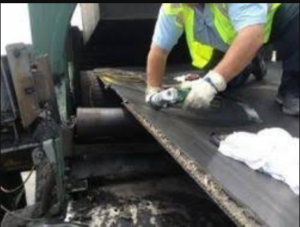

Heavy conveyor belts

Habasit’s heavy conveyor belts are interwoven or nonwoven in construction. These so-called US-style belts are highly robust, with enhanced puncture and tear resistance. They deliver a durable solution for the most challenging conditions, and come in a variety of different types.

Food belts

Newtop Engineering’s extensive range of food conveyor and processing belts features high-quality coating materials designed for all stages of modern food production, addressing the demands of various food processing applications.

These belts offer excellent release properties, even for highly sticky foodstuffs, along with wear- and abrasion-resistant coatings. They also provide superior chemical resistance to withstand common cleaning agents and food ingredients. Newtop Engineering belts deliver exceptional performance and long-lasting service life, fully complying with both EU and FDA regulations.

Processing belts

Newtop Engineering’s processing belts are specifically designed to meet the unique demands of a wide range of applications. Our belts cater to industries such as textile printing, wood panel board production, nonwoven production, and marble and stone processing.

By understanding the specific requirements of each industry, we help our customers achieve optimal quality and efficiency in their operations.

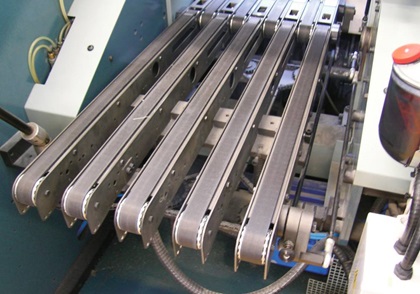

Folder Gluer belts

Newtop Engineering offers a wide range of folder-gluer belts made from various materials for different box folding applications. Our belts provide excellent reversed bending properties, high abrasion resistance, outstanding dimensional stability, consistent and secure grip, no marking of transported goods, and precise folding performance.

Elastomer covered conveying belts

Newtop Engineering’s elastomer-covered belts are available in a wide range of cover materials, strength classes, and surface structures, designed to meet the needs of various demanding applications. These belts support efficient and cost-effective processes, offering high abrasion resistance, a consistent coefficient of friction, and long-lasting performance.

Machine tapes

Machine tapes are essential in manufacturing operations within the printing and paper industry. They are used to convey, accelerate, decelerate, position, and, when necessary, fold processed materials. Newtop Engineering offers a comprehensive selection of machine tapes that deliver highly reliable belting solutions, providing consistent grip and ensuring long service life.

Power transmission belts

All our power transmission belts are tailor-made to suit specific industry and application needs or machine designs. We offer three different traction layer materials, used by three different belt concepts, for open drive, tangential drive, multiple pulley drive, live-roller drive, and double-sided power transmission. Habasit power transmission belts offer high flexibility, low energy consumption, and a long service life.

Seamless belts

Seamless and endless woven belts from Newtop Engineering are custom-engineered for exceptional performance and tailored to specific application requirements, especially where precision is critical. The unique manufacturing process of these seamless belts ensures smooth, vibration-free operation even at high speeds. With a wide variety of special coating materials available, these belts can be used in diverse applications where high grip, abrasion resistance, or heat resistance is necessary.

Spindle tapes

Newtop Engineering spindle tapes are designed to meet the demands of high spindle speeds, preventing fiber fly accumulation while ensuring reliable service life, energy efficiency, and cost savings in yarn processing. With a proven track record of maintaining consistent spindle speed and uninterrupted production, our spindle tapes deliver uniform yarn quality and cost-effective operation.

Tobacco belts

Newtop Engineering belts meet all current requirements of the tobacco industry, including pyrolysis resistance and food safety standards. These belts are designed to minimize contamination, thanks to their excellent release properties and easy cleaning capabilities. They also ensure a long service life, even in challenging conditions, and play a key role in enhancing overall plant efficiency.

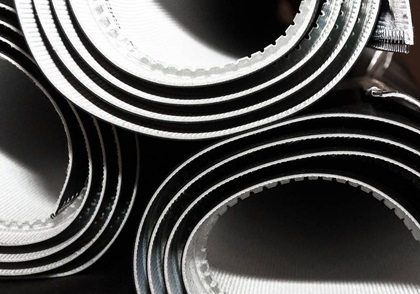

Newtop Fitline treadmill belts

Newtop Engineering Fitline offers a range of options for treadmill applications, including maintenance-free designs that require no lubrication. This eliminates the issue of wax build-up on decks or pulleys and ensures low, consistent energy consumption. Customers also enjoy benefits such as excellent tracking, high dimensional stability, durability, and an appealing design.

Discover how we can personalize your belt to meet your needs.

Discover how our advanced fabrication capabilities and the expertise of Newtop Engineering’s team can benefit your operations.

Experience energy savings with Newtop Engineering power transmission belts.

Estimate your potential energy savings with Newtop Engineering tangential belts.

Fabric conveyor belts surfaces

Conveying surfaces from Newtop Engineerings offer a diverse range of structures designed to meet the specific demands of various market applications. To explore the different surface structures and their properties, simply select the core features.

Basketweave structure

Buffed finish

Coarse textile structure

Cone top structure

Crescent top structure

Cylindrical knob structure

Diagonal rhomboid positive structure

Diagonal wave structure

Elliptical smooth netting negative structure

Fabric

Fine textile impressions / structure

Fish - herringbone structure

Glossy surface

Grip structure

Harlequin structure

Honeycomb structure

Impregnated fleece

Impregnated fabric

Inverted pyramid structure

Jink wave grip structure

Longitudinal groove

Matt, dull finish

Non-woven (fleece) structure

Orange peel

Orb structure

Pimple structure

Quadrillé (quadrangular pattern)

Sand Finish

Snake skin structure

Square structure

Supermatt finish

Super grip surface

Tear drop structure

Waffle structure