Power Transmission

Belts

Reliable belts that get things moving

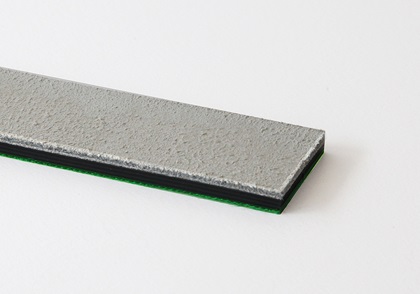

Newtop Engineering’s fully synthetic, high-quality power transmission belts feature a robust and durable traction layer made from polyamide, polyester, or aramid. The wear-, oil-, and grease-resistant friction covers, crafted from NBR rubber, ensure a high level of consistent friction between the belt and pulleys.

The versatility and energy-saving features of these maintenance-free belts make them essential in all aspects of power transmission technology. Their extended service life and minimal unexpected machine downtime provide a reliable solution for a wide range of industries.

Product Types

Discover our power transmission belts

The Newtop Engineering portfolio features polyester, polyamide, and aramid power transmission belts, tailored to meet the needs of a diverse range of machine designs.

Polyester Power Transmission Belts

Newtop Engineering has years of experience with polyester products across various industries and applications. This expertise has led to a product portfolio that offers an exceptional price-to-value ratio, making it the preferred choice of textile OEMs worldwide.

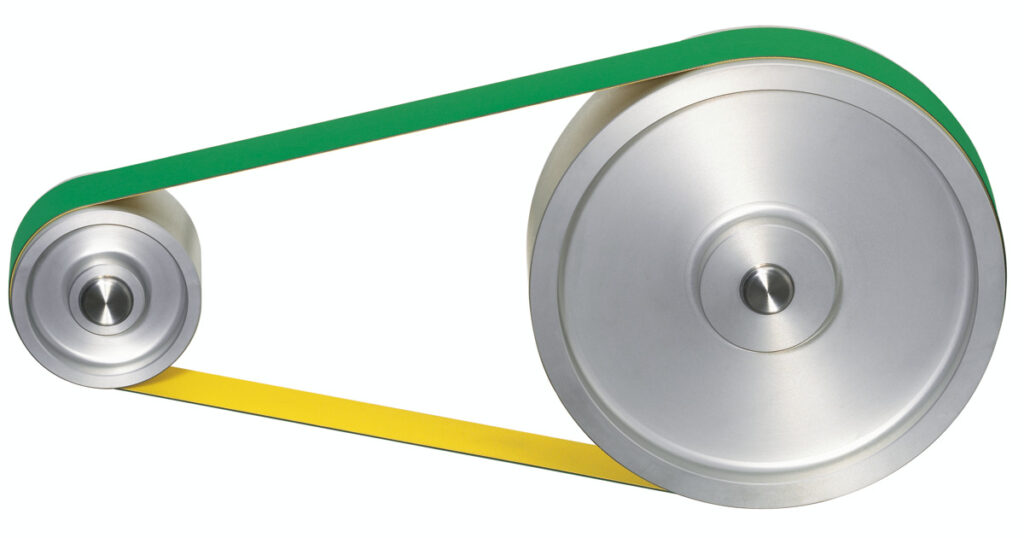

TC Tangential / Flat Belts

TC power transmission belts from Newtop Engineering are the ideal solution for compact driving configurations, serpentine drives, and extremely high speeds, particularly when used with reversed bending.

Main features:

- Symmetric belt construction, suitable for double-sided power transmission

- Low energy consumption

- Very high speeds possible

- Highly flexible

- Excellent reversed bending and flex fatigue properties

- Proven NBR rubber covers with high abrasion resistance

- Simple and fast to join (adhesive-free Flexproof method)

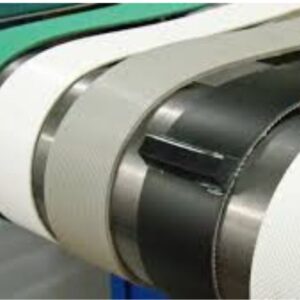

TCF Flat Belts

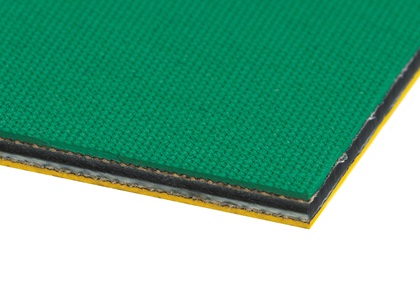

Newtop Engineering’s TCF flat belts are designed using TC technology but feature a single rubber (NBR) friction cover for open drives. These specialized belts are ideal for very small pulley diameters with a high number of reversed bends.

Main features:

- Longitudinal grooves enable high grip

- Low energy consumption

- Very high speeds possible

- Highly flexible

- Excellent reversed bending and flex fatigue properties

- Proven NBR rubber covers with high abrasion resistance

- Simple and fast to join (adhesive-free Flexproof method)

Polyamide Power Transmission Belts

Newtop Engineering’s polyamide belts are renowned for their reliability and extended service life, even in the most demanding applications and harsh conditions. The belts feature highly resilient traction layers that can handle intermittent overloads, effectively preventing residual elongation.

A Series Belts

The A range from Newtop Engineering is specifically designed for heavy open drives, where a robust construction and maximum durability are essential.

Main Features:

- Resilient design

- Shock resistant, very forgiving

- Longitudinal grooves enable high grip

- Operating temperatures up to 100 °C / 212 °F

- Proven NBR rubber cover with high abrasion resistance

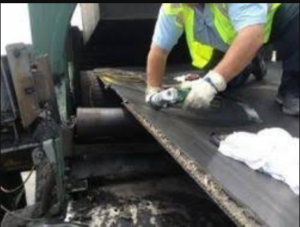

Leather Covered Belts

Based on the proven polyamide belt A series design, with the running side covered with high-quality leather, this range incorporates all the features expected of top-quality belts.

Main Features

- Resilient design

- Shock resistant, very forgiving

- Leather surface provides reliable grip and power transmission even in dirty conditions

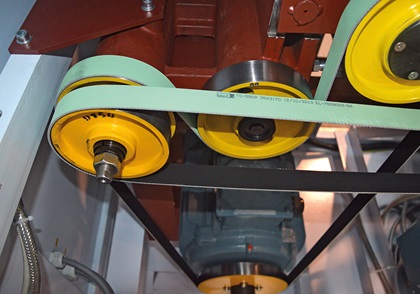

S & SP Series Belts

Newtop Engineering’s S tangential belts have been market leaders for many years. Especially in textile industry applications, this range provides numerous benefits, including consistent spindle revolutions, no need for retensioning, and an extended service life.

Main Features:

- Symmetric belt construction, suitable for double-sided power transmission

- Resilient design

- Shock resistant, very forgiving

- Good reversed bending and flex-fatigue properties

- Proven NBR rubber covers with high abrasion resistance

Aramid Power Transmission Belts

Newtop Engineering’s TF range belts are the optimal choice for very long applications where high accuracy and consistent belt speeds are essential. These belts offer numerous advantages, including a high modulus of elasticity that ensures exceptional spindle revolution uniformity, eliminates the need for retensioning, reduces energy consumption, and provides a long service life.

- Symmetric belt construction, suitable for double-sided power transmission

- Low energy consumption

- Highly flexible

- Excellent reversed bending and flex-fatigue properties

- Very high accuracy of rpm thanks to a high modulus of elasticity

- Very short take-up

- Extremely compact driving configurations (serpentine drive)

- Proven NBR rubber covers with high abrasion resistance

- Simple and fast to join (adhesive-free Flexproof method)