Tobacco Belts

Comprehensive solutions for the tobacco industry.

Newtop Engineering’s TPO and TPEE tobacco belts ensure smooth and efficient flow throughout every stage of the manufacturing process. We offer customized solutions tailored to your needs, from green leaf processing to primary processing, cigarette production, and logistics.

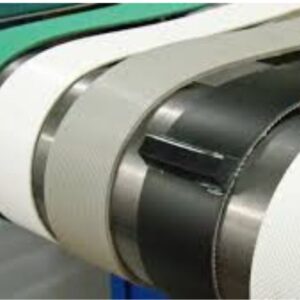

Newtop Engineering’s tobacco belts offer lateral flexibility, outstanding longitudinal stability, hydrolysis resistance, and anti-stick properties that resist moisture absorption. You can rely on their high abrasion resistance and anti-slip surfaces, making them ideal for steep incline applications.

Tobacco Belts

Newtop P line belts

Newtop Engineering’s P line belts have been specifically designed for the tobacco industry, utilizing the unique properties of TPO and TPEE coatings. To meet the strict safety standards required, our P line belts fully comply with pyrolysis regulations and FDA guidelines, and are approved for direct contact with tobacco.

P line belts enhance plant efficiency, reduce waste, and minimize contamination thanks to their superior release properties and easy-to-clean surfaces. Even in challenging conditions, these belts deliver reliable performance throughout their long service life.

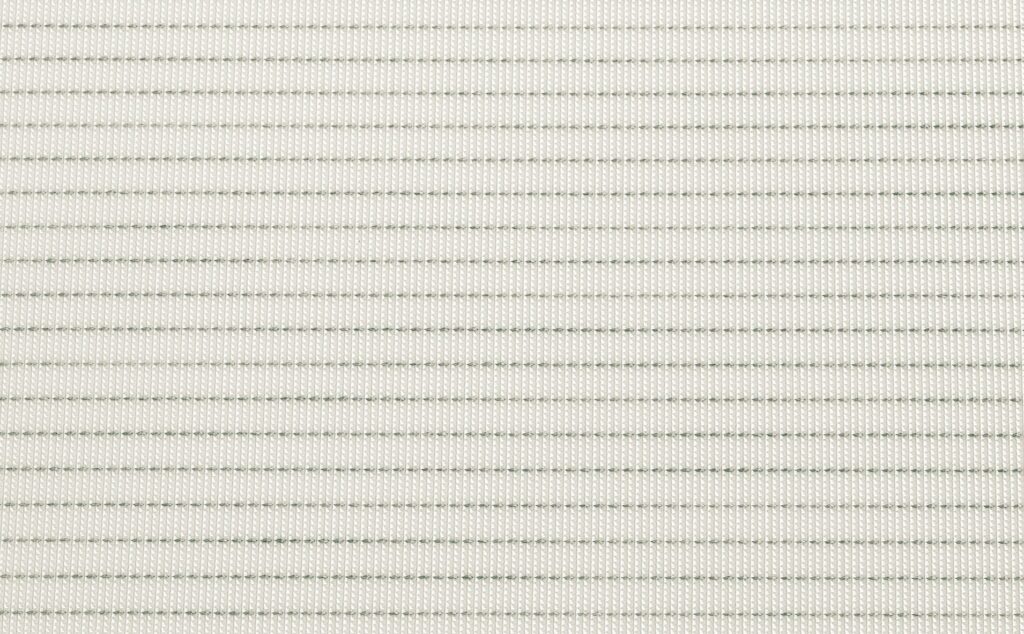

Belt surfaces and properties

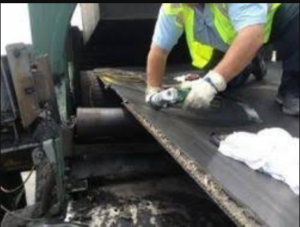

Belt surfaces are critical in tobacco processing, as they must perform multiple functions while enduring tough environmental conditions such as humidity, sand, soil, and mechanical impacts.

Explore our product range to discover the various surface structures and properties available with Newtop Engineering’s solutions.

- ONI series: Impregnated fabric, non-adhesive

- PAB series: Blank/smooth surface, adhesive

- PNB series: Blank/smooth surface, non-adhesive

- PAP series: Tear-drop structure, adhesive

- PAK series: Knob structure, adhesive