Nonwovens

Customized solutions for nonwovens

High-quality materials combined with our advanced manufacturing processes and years of expertise guarantee innovative and customized solutions for your nonwoven belting needs.

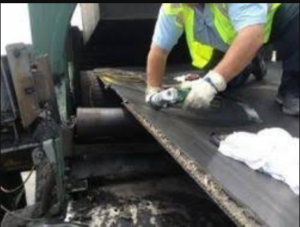

As your partner in all belting requirements, Newtop Engineering is here to assist you with every challenge. Whether you need to minimize downtime, require professional belt installation, or have other specific needs, we are dedicated to helping you achieve the highest performance for your operations.

We offer the perfect solution for your challenges.

Chemical resistance

Aggressive chemicals can harm the belt, leading to surface cracking and reduced service life. Newtop Engineering utilizes chemical-resistant materials that are non-brittle, preventing micro-cracking of the belt surface and ensuring an extended service life.

Anti-static properties

Our belts possess electrically conductive properties that prevent fibers from adhering to the belt due to static charges. This feature eliminates fiber buildup, helping to reduce unscheduled downtime.

Wear resistance

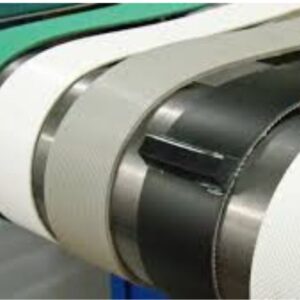

Due to their susceptibility to scratching and high wear, Newtop Engineering produces belts and covers that offer scratch and wear resistance, along with a low and consistent coefficient of friction. This contributes to a longer service life for the belts. Our crosslapper belts combine high transverse rigidity, lightweight construction, and exceptional mechanical properties, including lateral stiffness, good tracking, and enhanced scratch and wear resistance.

Precise positioning

Newtop Engineering can assist you in selecting the ideal solution for your needs, ensuring precise positioning and perfect tracking for optimal performance.

Specific surface structures

Different operations necessitate belts with various cover materials, specific embossing patterns, or particular thicknesses. Newtop Engineering offers the ideal surface structure to meet your precise application requirements.