Yarn Production and

Processing

Innovative solutions for yarn processing challenges

Textile mills operate under challenging environmental conditions, frequently facing high temperatures and significant fluctuations in relative humidity. At Newtop Engineering, our application engineers, technicians, and fabrication specialists provide tailored expert advice, exceptional customer service, and continuous support.

We offer a comprehensive selection of power transmission yarn processing belts, spindle tapes, and conveyor belts designed to meet the stringent requirements of yarn manufacturing, allowing you to choose the best solution for your specific application needs.

We offer the perfect solution for your challenges.

High belt flexibility

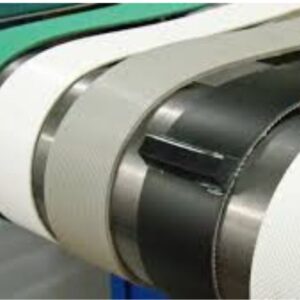

Small pulley diameters and frequent bending and counter-bending during operation require belts with high longitudinal flexibility. Newtop Engineering offers belts that fulfill these needs while also reducing energy consumption, such as our thermoplastic power transmission flat belts.

Good dimensional stability

Good dimensional stability ensures consistent spindle RPM, which is essential for producing high-quality yarn while also extending belt service life. Newtop Engineering enhances your productivity with belts that do not require retensioning and are resistant to elongation.

No slippage

Belts must operate effectively, even in demanding environments, without slippage or premature aging of the rubber covers. Newtop Engineering’s high-performance rubber covers prevent slippage and provide a consistent coefficient of friction.

Abrasion resistance

Conveyor belts designed for handling full bobbins need a durable conveying surface, which is a hallmark of Newtop Engineering’s solutions for the textile industry. To ensure extended belt life through superior abrasion resistance, Newtop Engineering offers high-performance rubber covers for power transmission belts. For spindle tapes, both the fabric surface on the whirl side and the rubber or thermoplastic polyurethane cover on the driving pulley side provide excellent abrasion resistance.

High temperature and humidity resistance

To address the challenges posed by significant fluctuations in temperature and relative humidity, Newtop Engineering belts provide excellent bonding between layers to prevent delamination and elongation. In particularly demanding environments, we recommend our polyamide power transmission flat belts, which offer exceptional resistance to high temperatures, as well as our latest generation of thermoplastic power transmission and tangential belts.

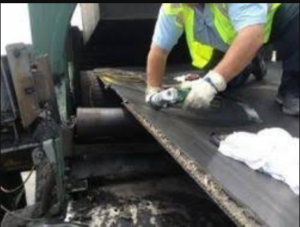

Strong and reliable belt joining

Given the highly demanding operational conditions, power transmission belts must be expertly joined. In hot and humid environments, the strength of the joining area can be optimized by choosing polyamide belts that require the Thermofix joining method from Newtop Engineering.